In the world of venture capital and private equity investors, the quest for lucrative acquisitions and profitable exits is unrelenting. Mergers and acquisitions (M&A) in the food industry are commonplace. Despite the macroeconomic factors, strong headwinds from the geopolitical climate, rising interest rates, raw material costs, and inflationary pressures causing a lull in late 2022/early 2023, the appetite for strategic investment remains very strong.

The food industry has seen huge change driven by health-conscious consumers, plant-based alternatives, preferences toward sustainability, technological advances and delivery apps. The investors out there are keen to get a slice of the new pie, with funds being set up specifically for sustainable or vegan portfolios.

Whilst the volume of M&A remains high, the value of those deals is comparatively small, partly due to a lack of and risk of big deals available, but more so because these new industries are start-ups and in their infant stages. Of note, more than 25% of the deals in the last 3 years have been distressed purchases.

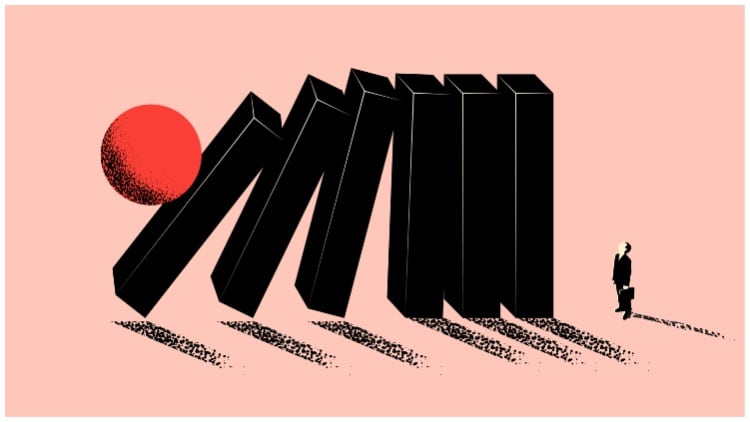

When buying, selling or investing in a new business, the due diligence process is critical for assessing the company’s viability. The suits go in. However, amidst the excitement of finance, commercials, deals and negotiations lies a critical aspect often overlooked: understanding the operational heartbeat of the target business.

The essence of operational due diligence lies in comprehending how a business truly functions. This goes beyond desk top assessments; it entails getting into the weeds and understanding the interplay between systems, processes, machinery and the people. Knowing the operational performance and theoretical capability is worthless if you don’t know why, and what needs to be done to fix it.

Why do so many deals get completed without undertaking a robust operational due diligence? It isn’t financially motivated, an extra £40k on top of the millions spent elsewhere is a drop in the ocean.

Is there a blind assumption that the operation will just ‘fix itself’ or that it must be operationally fit if the numbers stack up? The number of distressed sales and inefficient businesses we see dispel that myth too.

So why, when so much is at stake, is operational due diligence ignored?

Navigating the transition: from purchase to value creation

Armed with operational knowledge of the target business, investors are empowered to navigate the post-acquisition landscape with confidence and clarity. By leveraging the insights of a robust operational due diligence audit, they can strategically allocate resources, implement targeted interventions and seize opportunities to increase value.

From fine tuning systems and processes to enhancing workforce productivity, the roadmap to profitability becomes significantly clearer. Whether that is knowing the people who need to leave, the machines that need mending, the processes that need fixing, or the systems that need addressing.

It is not unrealistic to find up to 15% improvement opportunity in labour usage and material variances. Knowing that upfront and targeting it from the outset steadies the nerves in the early days, assuming of course that the due diligence did not put them off the deal in the first place!

A two-week diagnostic that looks at how machines operate, the organisational structure, behaviours and competencies, productivity, efficiency, as well as the systems they have, the processes that run the business and how it is managed. It is of equal benefit to understand what is in place and what is missing and the impact these missing elements have on the function of the operation.

Seamless portfolio integration: The key to growth synergy

For investors with existing portfolios, integrating a newly acquired business poses a unique set of challenges. Here lies the importance of aligning operational strategies and harmonising the disparate elements within the portfolio. More often the new purchase will form part of a new ecosystem and there will be synergies and economies of scale that can and should be attacked. The operational due diligence in this instance should extend to the current portfolio to understand where products and machinery may best be collated for better planning, supply chain links, reduced changeovers and all manner of financial opportunities.

The question is do those ‘doing the deal’ have the intricate knowledge of their existing portfolio to understand everything they ‘see’ in the target. Most likely the answer is ‘no’. They will be interested in balance sheets and cashflows and P&Ls, but probably not whether the production lines have the capacity and capability to handle new SKUs or if the ERP systems can be integrated with minimal disruption.

I would argue, even without any impending investment, there is a significant benefit in understanding your portfolio better and others are seeing that too. This is why interaction with venture capitals and private equity has been the biggest move in our business over the last 18 months.

Maximising the value on exit: the importance of pre-sale optimisation

In the pursuit of maximising selling price and securing favourable multiples of EBIT (earnings before interest and taxes), pre-sale optimisation of the operation emerges as a pivotal strategy. Through a meticulous analysis of operational processes, efficiencies and waste, the business can identify areas ripe for improvement. Whether it is enhancing productivity, reducing material losses or improving supply chains, every incremental enhancement translates into bottom line profit. Improving operational efficiencies by £1m could add £8m to the selling price – what’s not to like?

How many of the distressed businesses sold in the last three years would have survived if they had undertaken some form of operational improvement? It’s hard to know an exact number without seeing them all. Typically an operational turnaround delivers a minimum 15% efficiency, so even if distressed, they would have had more value.

There are stories weekly of businesses bought and flipped and we all revel in how amazing the private equity folk are for delivering such value – and they probably are amazing - but how much of that turnaround was simple operational efficiency that you should have fixed before selling up?

Having spoken to numerous investors and advisers they all agree a common theme is the lack of a robust operational due diligence.

In short: do your research

The push for investment opportunities will continue, likely there will be growth in newer industry segments as people look for ‘green’ investments. Whether that’s consolidation in the meat-free industry, moving to sustainable businesses, or the rapid rise in challenger brands looking to get swept up for a big payout, the landscape is changing.

What remains constant is they all use the same systems, the same processes and have people at the heart of what they do, so at least try to understand them before wading in.

In other news, Food Manufacture rounds up the latest raft of food and drink recalls, including Sainsbury's own brand of flaked almonds which were found to contain Salmonella. Find out more here.