We speak to the brand’s founder and chief executive officer Moayad Abushokhedim about its plant-based sugar substitute solution and its wider plans to tackle global sugar intake.

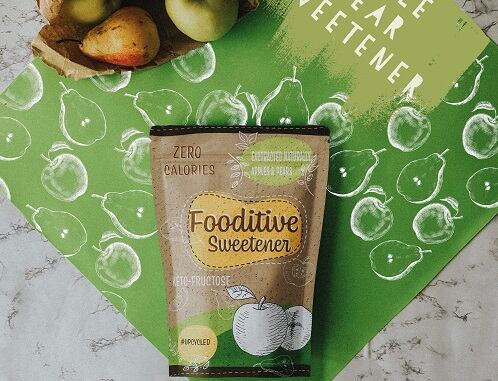

Sugar substitutes are not often synonymous with being healthy and natural, but that's the focus of Dutch plant-based ingredient and sweetener innovator Fooditive. Launching in 2018 with its plant-based and chemical-free sweetener, Fooditive centres its efforts on improving the health status of products that use sugar replacements by providing an affordable alternative.

The inspiration behind formulating its sugar substitute sweetener

“Nowadays, an increasing number of consumers know that excessive sugar intake can lead to many health issues,” explains Abushokhedim. “The food industry is looking for sugar replacements that do not compromise on taste and functionality.”

Aiming to start a food company that has a real impact on people’s lives while understanding the difficulty of this goal, Abushokhedim began researching how to produce a sweetener that benefited the body and the planet.

The company began exploring the properties of a sweetener that could successfully replace sugar in food products. To do so, the team examined the science behind sucrose, its taste and its unique functionalities.

Fooditive believes the key to sustainable sugar-replacement solutions is sourcing pure and natural raw materials. With its mission to delve into the use of sustainable solutions to combat the world’s sugar intake, the brand set about understanding the use of plant-based ingredients to help it achieve this.

Made from waste

The company’s sweetener is made from the waste from the production side streams created by processing apples and pears, which is then subjected to continuous fermentation enzymology. This process leads to the extraction of fructose from the raw material, which contains a high sugar content, and the transformation to keto-fructose via bio-refining methods.

Once the process is underway, the product is spray dried to 99.5% purity. “Through this unique approach, Fooditive has created a zero-calorie sweetener," Abushokhedim explains. "Production is environmentally friendly and cheaper compared to similar ingredients on the market.

The innovator notes its unique approach to producing its sweetener leads to 25% fewer CO2 equivalent emissions than traditional sugar production.

“Sugar cane production does require a high amount of water for farming and the production process of sugar leads to high CO2 emissions. It takes about 210 litres of water to produce 1kg of sugar while Fooditive’s sweetener only needs 125 litres of water to produce the same quantity.”

Reverse engineering sucrose to create sugar substitutes

Fooditive hopes to achieve breakthroughs in valorising plant-based side streams for use as natural sugar replacers in food applications. The company follows a unique methodological approach to developing sugar substitutes, the reverse engineering of sucrose.

The business's starting point is studying products containing sugar and its qualities in order to fully understand its role in taste and functionality. By applying scientific know-how on the physical and chemical properties of sugars and their effects on the perception of sweetness, the company works backwards to get the ideal properties that a sweetener should have to successfully replace sugar in food and beverage applications.

“Assays for product functionality such as texturising/bulking and sweetening, and process monitoring tools are being developed to speed up innovation."

Formulation challenges

Detailing the key considerations during the technical production process, Abushokhedim says: “The right choice of raw material is the first crucial point in the production process, as the fruit is fermented using yeast to yield the keto-fructose sweetener.

“In addition, as fermentation is a quite conventional and slow process, it requires more time in the bioreactors; at least 48 hours of production."

Fooditive recognised this time would affect the cost of its end-product. However, the team's use of continuous fermentation has reduced production time to seven hours, enabling a higher yield of sweetener in a shorter time frame.

“Fooditive’s core principles align with the development goals for sustainable production and the transition to a circular economy model,” highlights Abushokhedim.

Collaboration with farmers

In addition to drawing on the byproducts of processing these fruits, Fooditive collaborates with farmers to salvage organic and non-organic unwanted apples and pears.

The business's weekly goal is to produce approximately 30 tonnes of sweetener by upcycling 83 tonnes of third-grade fruit. As the brand aims to reuse upcycled materials, there is one important supplier requirement: the raw material must be safe for the end-consumers and not contain any harmful substances.

The company also aims to collaborate with production partners in using clean and zero-genetically modified materials.

“For the production process of Fooditive’s sweetener, the aim is to work with companies who deal with either supplying and distributing the fruit or companies that produce natural juices,” Abushokhedim notes.