The company has claimed the approach would suit the makers of pizza, cakes, bread and scones.

The on-site trial indicated that even when solid and viscous dough was mixed with baked bread, the pumping system remained successful.

Products of this type are notoriously difficult to pump, owing to the variety of materials involved and their propensity to block product flow out of hoppers.

New system

The existing manual system used before the Seepex trial often resulted in manually removed waste dropping on to the floor, creating a potentially hazardous environment.

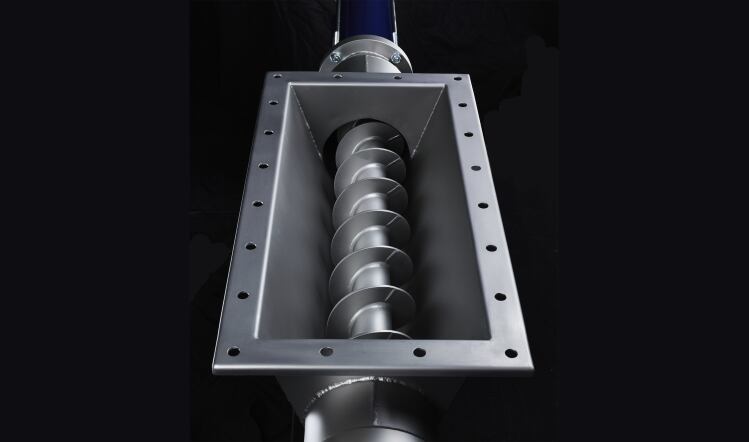

Seepex’s BTM open hopper pump uses an auger to mix the different products, and rotating knives to reduce particle size.

The new system is automated and largely enclosed, improving hygiene standards. The only open part is the hopper, which requires loading. Aside from that, everything is enclosed – even the delivery of waste to a removal lorry, which takes the waste for recycling at an animal feed company.

Energy efficient

The level controls inside the hopper meant the pump only started running when there was product to handle, and stopped the moment the hopper was empty, making it extremely energy efficient, Seepex claimed.

In addition, the level of automation means only one person is needed to load product into the hopper, freeing up more people to focus on production.

“During the trial, every possible combination of product mix was tested, at varying volumes,” said Seepex applications engineer João Rodrigues. “The system coped well with every variation and the client requested no changes from the preliminary solution we proposed.”