In this exclusive interview, Iverson talks about the practical application of robots and robotic systems in food factories and their wider impact on the food manufacturing industry.

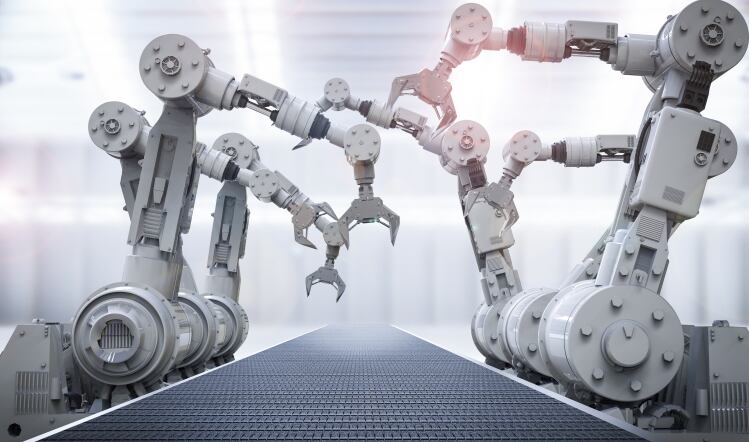

When asked what was driving the adoption of robots by manufacturers, he said: “Food and drink, the whole industry has seen the same advantages of getting robotised as many other industries previously, so it’s really a question of making sure your business can stay more competitive and become more competitive in the global marketplace – that’s the main driver.

‘Technological developments’

“Part of that is also the technological development where the technology allows for much better cooperation between robots and humans, but also with vision systems that allow for quality inspection applications that were not previously available.”

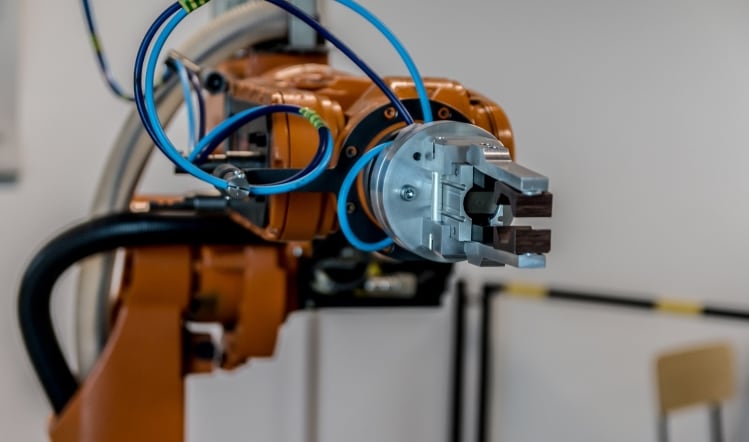

Iverson went on to discuss the role of factory floor workers as the adoption of robots becomes more widespread, as well as the cost of robots and how this can prohibit manufacturers from adding the tech to their production lines.

Costs coming down

“The cost of the total application has come down with both the entrance of collaborative robots and more intelligent tools on the robots,” Iverson added. “Today, if you look at the investment, in most cases you will have payback times that are less than a year. The best robotic applications have a payback of two to three months.”

Meanwhile, collaborative robots can help reduce labour costs and take on the more boring repetitive tasks in a plant, but how flexible are they and how much resistance is there to their presence in the workplace? Or will manufacturers resist the robot revolution?