It’s been a case of too much, too young for the alternative protein category.

“There was a huge hype around alternative proteins, and it went up and up and everybody was excited, and then COVID came and it grew even further because people were concerned about health,” says Maarten Geraets, managing director of Alternative Proteins at the Thai Union Group.

“Then when COVID ended, they all went back outside again and forgot about healthy eating and plant-based. What you see now is the category is a little bit under pressure.”

Beyond the capriciousness of consumers released from lockdown, factors contributing to the deflation of the plant-based bubble have included criticism of the category’s environmental and nutritional credentials as well as the all-important taste experience.

“Overall, plant-based has received a lot of consumer trust,” says Geraets, “and if we don’t live up to those expectations and people get disappointed, they will walk away.”

He believes the next few years offer an opportunity for the category to reset and rebuild on a more solid foundation focused around the right ingredients, nutrition and “top notch products that people want to come back to”.

“We need to take the consumer on a journey and I’m absolutely confident it will happen, but it will take longer than people thought,” he says.

Christoph Jenny, co-founder of Swiss foodtech start-up Planted, concurs. “It’s not going to be a one or two-year thing,” he says. “You see these companies rush to an IPO, but it takes time to build the category and convince consumers.”

Hybrid solutions & clean labelling

“The challenge is to create alternative proteins that match meat through taste and choice,” says Caroline Jary, plant business unit director of The Compleat Food Group, UK owner of the Squeaky Bean brand.

Launched three years ago, Squeaky Bean lays claim as the leading brand in ready-to-eat chilled meat alternatives, producing pea and grain-based slices which are high in protein and low in saturated fat.

Its range features ham, chicken, pepperoni and pastrami-style slices, and chicken-style pieces and fillets, with recent NPD including Horseradish Beef Style Slices with a horseradish crumb and Chargrilled Steak Style Strips.

Jary cites Kantar research identifying growth opportunity among consumers reducing or removing meat consumption as well as snacking and breakfast occasions.

“We’ve conducted significant research into the motivators behind these groups and, foremost, they are united in wanting great tasting food they choose to eat, not because they have to,” she says.

Thai Union, a global supplier of seafood with John West among its brand portfolio, diversified into alternative protein two years ago. It has already launched plant-based tuna, crab and shrimp produced from soy and wheat, and is developing yellow pea-based products.

“We are just out of the starting blocks,” says Geraets. “The difficulty with pea is it’s a much newer ingredient versus soy, which has been around as a texturiser for many years.

“Taste, texture, aroma and of course price are very critical to succeed in the category and I would argue that big jumps have been made in progressing to better products.”

However, there is still much room for improvement. “Industry has to work on new technologies,” he says. “It could even be a mix, a hybrid of cell-based and plant-based solutions. We’re working on all the different options to see which one mimics best what we want to achieve in the marketplace.”

Planted, created three years ago as a spin-off from the Swiss Technical Institute, combines protein structuring and fermentation to biostructure its products, with fermentation building out its products to deliver on juiciness and taste.

Clean label formulations are its USP with its latest launch, an additive-free whole chicken breast-style product, produced from yellow peas, water and rapeseed oil.

Sustainability focus

Sustainability is also a focus, with the foodtech company particularly proud of its pulled pork-style product, produced from oats, peas and sunflower press cake, a waste product from sunflower oil production.

“The direction we’re going in is the whole cut space,” says Jenny. “Larger cuts like chicken breasts give consumers that versatility of using it not only in a curry or a fajita wrap, but in general across their daily usage.

“We want to be better for taste, price, the environment and health, which we felt was highly neglected by some of the early movers in the space. Every bit of consumer research we do says what holds people back is not knowing what’s in the products and if it’s good for you or not. We have to do a lot of education.”

Alexandra Clark, co-founder of UK investment fund Sentient Ventures, also identifies consumer concerns about health and nutrition as a barrier to growing the category.

“Consumers are starting to request more nutrient dense and cleaner label products with fewer ingredients,” she says. “There is an important opportunity for the development of ingredients and technologies for B2B with better nutritional profiles and functionalities.”

Clark says common plant-based protein sources such as soy, wheat and pea face many drawbacks from allergies, and climate, trade disputes and war impacting food supply chains, to issues with organoleptic properties including texture and aftertaste.

Sentient is supporting research into underexplored and underutilised leguminous crops and grains with the potential to offer better nutritional properties and functionalities and highlights algae as a high-potential sustainable and nutritious protein source.

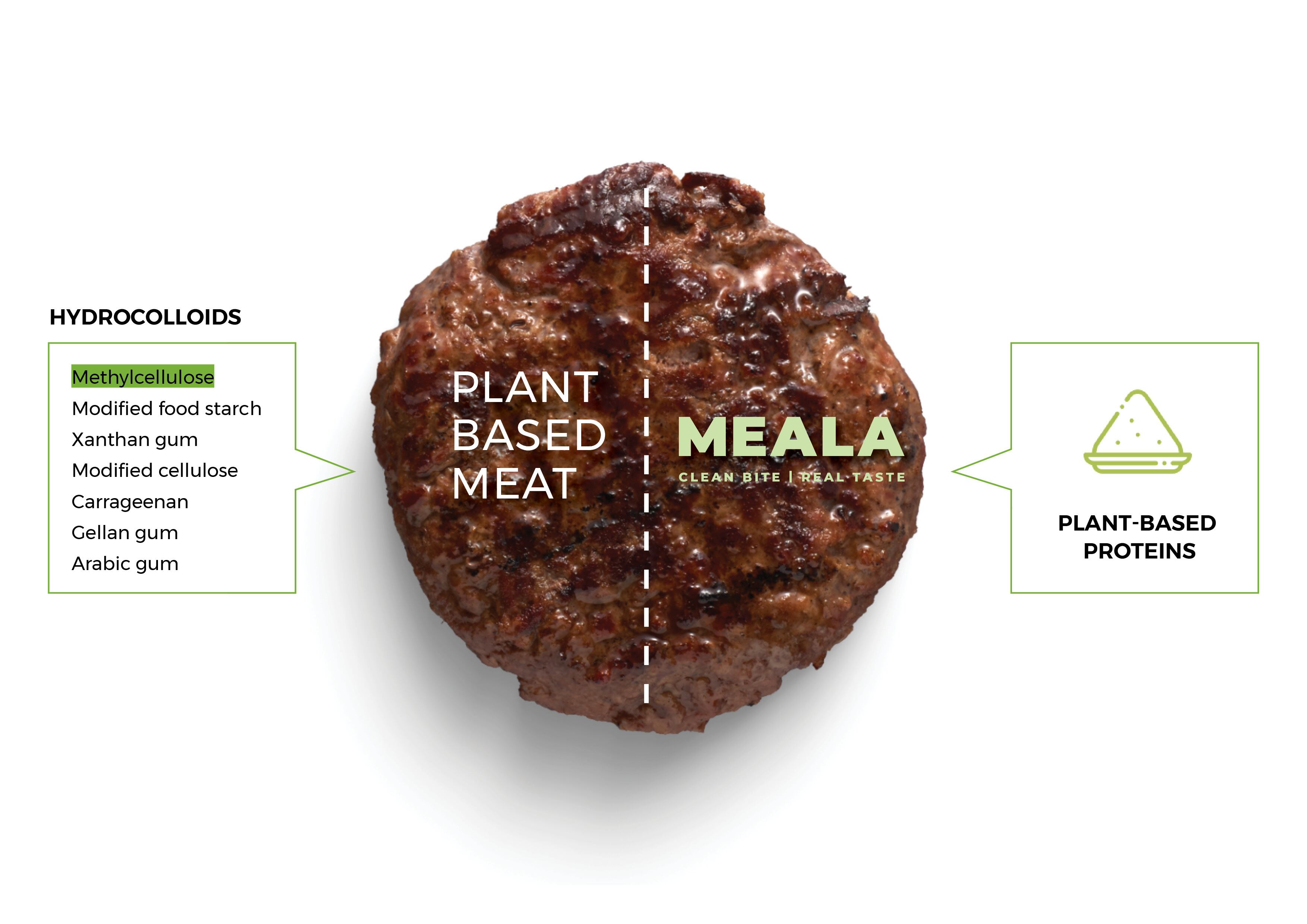

For manufacturers seeking cleaner label solutions, Israeli foodtech start-up Meala offers alternatives to methylcellulose and other hydrocolloids, using proprietary technology to turn plant-based proteins into super functional products offering improved binding and water retention as well as better and juicier texture.

Its products, which have been trialled in plant-based burgers and kebabs, can be labelled as a protein such as pea or soy.

“If you break down the ingredients list of a real meat burger, its composition will be meat, fat, some carbohydrates, spices, salt and pepper,” says Hadar Razmovich, chief executive and co-founder of Meala. “Our vision is for plant-based alternatives to sport a similar short list of simple, recognisable home kitchen ingredients while delivering the same full-bodied flavour and texture of real meat.”

Longer-term prospects for some alternative proteins

Insect and air proteins and cultivated meat are among alternatives in development, but perhaps longer-term prospects for the market.

“Some of them are quite distant because, from a regulatory point of view, they’re not allowed yet,” says Geraets, “and we also don’t know how to make them yet in large scale.”

While only operating in plant-based and fermentation itself, Thai Union has created a corporate venture capital fund investing in start-ups developing insect proteins and cell-based solutions.

“If you look at cell-based technologies, for example, they are probably five to 10 years out before they can really bring a product to the market in a large scale,” says Geraets.

With insect-based protein, the feed sector could serve as a market entry point. “You often hear about the yuck factor,” he says. “The consumer is not yet ready to eat insects.”

Geraets believes the category will evolve beyond mimicking traditional proteins. “Eventually we will get to a whole new category, and it may even look like tofu or tempeh which are very traditional alternatives in the protein space,” he says.

Israeli foodtech start-up BioBetter recently secured funding for its work harnessing tobacco plants as bioreactors for creating the growth factors (GFs) necessary for the cellular development of cultivated meat.

“This disruptive technology enables unlimited capacity and a flexible solution that will allow the cellular agriculture industry to become commercially viable by providing commodity cost and scale GFs,” says Amit Yaari, chief executive, BioBetter.

Within cultivated meat, “there are many exciting developments that include improved textures and novel tastes, some of which may even surpass existing meats,” says Yaari. “Whole cut steak can now be designed for organoleptic perfection in terms of fat content, composition, tenderness and minimisation of undesirable components such as facia and cartilage.

“Simpler products such as nuggets and burgers are closer to market but, seeing the pace that steak tissue engineering is progressing, I think the first products will be marketed within a few years.”

Yaari also identifies exciting prospects around air protein, using similar technology to BioBetter’s partnership with tobacco plants. “The question is, how well can this process be performed in a bioreactor, and will it be as energetically efficient as plants are,” he says.

Another Israeli business, Steakholder Foods, is producing Omakase Beef Morsels, a 3D-printed cultured meat product emulating the marbling standard of Wagyu beef.

Composed of multiple layers of muscle and fat tissue, each layer is printed separately using separate bio-inks for muscle and fat with flexibility offered to produce a variety of muscle/fat sequences in any marbling ratio, shape or width.

Automation and technology are advancing developments across alternative proteins with Planted, for example, able to bring down its pricing by gearing up production from 30kg three years ago to a current one tonne per hour per line.

For traditional meat manufacturers moving into the plant-based space, Rockwell Automation recommends investment in a manufacturing execution system to handle the more complex ingredient tracking, tracing, quality and recipe requirements.

IoT technology, meanwhile, can inform real-time decision-making to improve yield, productivity and quality, helping alternative protein manufacturers achieve the holy grail of closer price parity with traditional meat.