From machinery offering output that matches the quality of hand-made products to developments in cutting technology to reduce energy use, equipment suppliers are moving swiftly to meet food and drink processors’ needs.

In the wider food and drink space, automated technologies – and in some cases the use of digitalisation – have allowed manufacturers with traditional production processes to enter the 21st century while maintaining product quality.

For example, salami and raw sausage manufacturer Sorger has boosted production while still maintaining the quality of its products in collaboration with equipment supplier Handtmann.

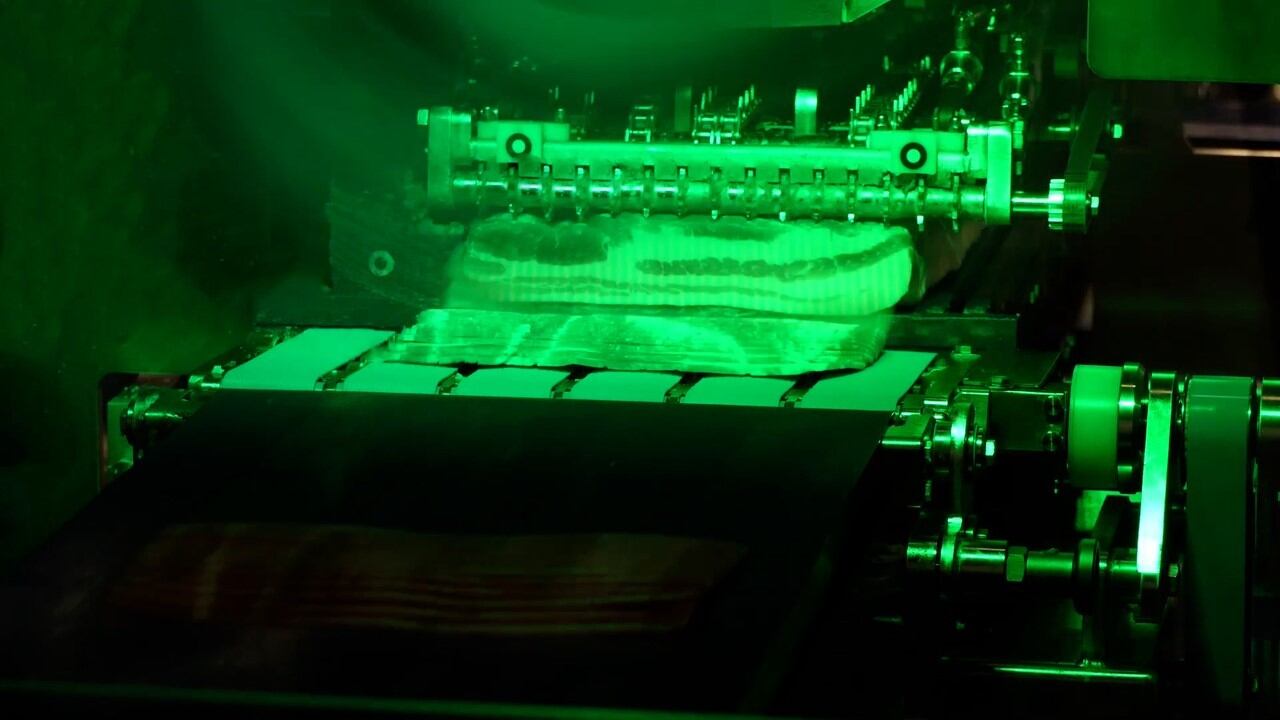

ConProLink technology for Salanetti salami

The manufacturer has used Handtmann’s ConProLink technology in the production of its Salanetti salami snack. The system has also been used in the production in its other raw and cooked sausage lines, thanks to its reported flexibility, high portioning accuracy and reliability.

Handtmann says its PVLS 143 linking and cutting line and VF 838 S vacuum filler and GS 301 collating system has allowed Sorger’s products to maintain a ‘handmade quality’.

According to Sorger, the partnership has helped bridge the gap between tradition and modernity.

“It is the very fine adjustment of product data, such as shape and end of the product, that makes the production of our quality products possible after all,” said Peter Kroyß, head of production and product development at Sorger.

‘Production runs smoother’

“Working with this line is considerably more pleasant than before. Despite higher output, production runs smoother and thus with less strain on the staff.”

Indeed, even with a smaller headcount, the manufacturer has been able to achieve a production output increase of 15% since the installation of the Handtmann lines. Sorger attributed this increase to a lower amount of stress and a streamlined production process.

However, while producers such as Sorger have achieved great success through the integration of equipment into its production, some are unable to implement similar results due to a lack of space.

With floor space often at a premium for manufacturers, especially smaller businesses without the capital to expand their working area, careful consideration must be made to ensure new cutting or slicing lines will fit.

Interfood’s compact Astech SRA bandsaw

Interfood’s latest offering – launched in the UK and Ireland in January – is a new compact version of its Astech SRA bandsaw, developed after market research highlighted demand for a machine with a smaller footprint.

Like its bigger brother, the SRA Compact offers automatic cutting of frozen and fresh bone-in or boneless produce. Flexible programming offers a range of variables with the capacity to store up to 50 cutting recipes for meat, fish and other products.

Commenting on the machine, Richard Nethercot, group divisional manager, low risk, butchery division, at Interfood, said: “For some food processors, optimising space has always been a challenge but with the need for social distancing, it has become a consideration for even more.

“Consequently, finding ways in which automated processes can be performed by machines with a smaller footprint has taken on greater significance.

“This new compact SRA offers the performance often associated with much larger machines, with impressive statistics regarding production per operator.”

High quality cuts to a precise thickness are generated through adjustable speed control, with safe and easy operation ensured through a user-friendly interface.

GEA’s involute blade for frozen food

Many meat processors are seeking to make the most efficient use of energy as well as space. For those slicing frozen meat products, GEA has developed a new involute blade that features a saw-tooth edge for use in its machines.

GEA guarantees the blade will provide high-quality slicing without the need to first crust freeze products, such as cooked sausage and ham. By saving the cost of having to freeze the product, GEA argues the blade provides a direct and sustainable improvement to company’s energy footprint.

No retrofitting is required, with line operators only needing to change the blade on their machinery.

Business advantages clear

Norbert Brunnquell, GEA senior product manager for slicing & loading added: “From a business perspective, the advantages are clear: The new blades eliminate the need to form a hard crust on the product using an expensive and energy consuming nitrogen crust freezing process.

“Likewise, they slice soft, fragile products accurately and precisely. Preparation time is shortened and the slicing process itself is simplified when crust freezing the product surface is taken out of the equation.”

Saving on floor space was also a key design principle behind a new dedicated slicer for belly and turkey bacon from bacon slicing expert Thurne.

Thurne two bacon slicer

The Thurne two bacon slicer maximises on-weight and yield performance in a compact footprint, thanks to high precision feed tracks and the use of highly accurate vision technology. Thurne claimed flatbed design enabled cost effective continuous, high throughput slicing with minimum reload time.

As vice president of sales Mark Douglas explained: “We’ve designed the Thurne ‘two bacon’ to deliver proven Thurne technology at a competitive price. It’s the go-to bacon slicer for the US market: high throughput; high yield; high on-weights – low giveaway, low maintenance.”

The slicer interfaces with Thurne and Middleby’s integrated bacon processing systems, which include the brands’ upstream and downstream equipment, from belly loaders to sheeters and thermoformers. An external trim reject option is available to maintain a clean line for sheeted and carded applications.

Grote’s Slicer Applicator

Ease of use is also the name of the game when it comes to new slicing equipment, a core design concept that fueled the new version of Grote Company’s Slicer/Applicator.

Grote has also completely redesigned the AccuBand Blade System that the machine employs in a bid to improve blade and blade guide life. The system has easier set up in mind too, with an updated blade guide mounting system allowing for quick changeouts and sanitation, resulting in consistent performance and less downtime.

Other features included an open channel frame with no hollow tubing, a watershed electrical enclosure, IP69K motors and easy access for maintenance and set-up via telescopic guarding.

Slices a wide range of products

The Slicer/Applicator slices, then applies a wide range of food products directly onto processing lines with precise targeting. It is used in the production of well-known products around the world such as jerky, sandwiches, bread snacks, and frozen and to-go meals such as cordon bleu and lasagna.

“The Slicer/Applicator was our second slice-and-apply machine over 30 years ago, after the Pep-a-matic, and we are proud to continue its tradition with this new, superior design,” said chief executive Bob Grote.

“We optimised and improved several components of the slicer, all to increase performance and sanitation, while decreasing downtime and total cost of ownership over the many years it will run.”

As the world moves increasingly automated and manufacturers continuously search for ways to integrate new tech into their production lines, slicing equipment suppliers are clearly keeping pace with the changing needs of manufacturers. The only question is where the next step in this evolution will take them next.

Case study: Ornua Foods

Last October, Ornua Foods UK announced a £3m investment in its cheese cutting and packing equipment at its Leek facility. The investment supported the installation of an additional high-speed slicing line and the further expansion of Ornua’s cheese grating capabilities, reinforcing the Leek plant’s position as the UK’s largest and most efficient cheese packing facility.

The equipment went ‘live’ in January, delivering an additional 7,000 tonnes of slicing and grating capacity and bringing total annual production capacity at Leek to more than 110,000 tonnes.

In addition to boosting capacity, Ornua claims the new slicing line (one of four at Leek) has delivered greater efficiencies and yield improvements.

The line has a reduced labour requirement and improved throughput thanks to handling four sticks of cheese from input to output. That has reduced the manual handling and labour involved and improved throughput by up to 15%, depending on product, the company says.

Ornua is also trialling advanced technology on front-end slicing equipment that scans each stick of cheese and adjusts the cut position based on block shape. According to Ornua, initial results proved very promising, with improved yields and reduced wastage week-on-week.

The operations team believes the performance and consistency will continue to improve helping Ornua meet strong growth in a sector of the market where sliced volumes are growing by more than 5% a year.

Bill Hunter, Ornua Foods UK’s managing director, says: “Ornua’s success is based upon our commitment to delivering a comprehensive range of high-quality products to our retail customers in the most consistent and efficient manner possible.

“Our latest investment at Leek has further enhanced our cheese packing capacity and capabilities delivering further improvements in yield and efficiencies.

“However, we are not stopping there, and in line with our longer-term strategic growth plans, we are set to make further investments at Leek, which will continue to give us a competitive advantage in the marketplace.”