Eagle eyes on advanced inspection

The specialist firm said food manufacturers could cut down on waste by better discerning between acceptable and unacceptable products. Advanced X-ray systems could improve detection of physical contaminants, even in difficult-to-read products, to reduce the amount of false rejects during food production, it added.

Eagle’s systems could simultaneously conduct quality checks – such as weight, fill level and component count – and determine if foreign materials had affected the proper package seal.

Reduce or nearly eliminate false rejects

The company said it was continuing to hone its other capabilities to greatly reduce or nearly eliminate false rejects, with machines that could more accurately detect a broader range of foreign bodies.

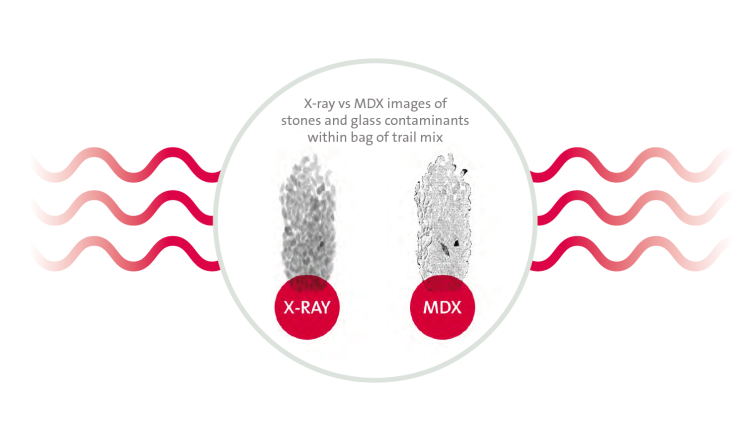

“Eagle’s MDX dual energy and SimulTask™ PRO image processing software, have been shown to significantly reduce false reject rates that can lead to loss of both products and profits,” said Christy Draus, marketing manager for Eagle Product Inspection. “SimulTask™ PRO offers up to 65,535 greyscale values – the highest on the market.”

The next-generation dual energy MDX technology on the Eagle Pack 400 could detect smaller bone fragments with a 99% accuracy rate, she noted.