Promotional Features

Multihead weighers add consistency to the mix

Multihead weighers offer food manufacturers a vital edge as they strive to meet the requirements of their customers. With supermarkets and the food service sector insisting on ever more exacting specifications, it is crucial that food manufacturers maintain consistent quality on their production lines.

Multihead weighers: what they offer

- Measure precise qualities

- Quick and reliable operation

- Minimise waste or giveaway

- Small factory footprint

The vast majority of food products are sold by weight, so measuring out precise quantities, quickly, time after time, with as little waste or giveaway as possible, is vital, and this is exactly what multihead weighers are designed to do.

The first multihead weigher was developed by Ishida in 1972 and although there have been many innovations and enhancements since then, the 'combination method' of how they work has remained the same.

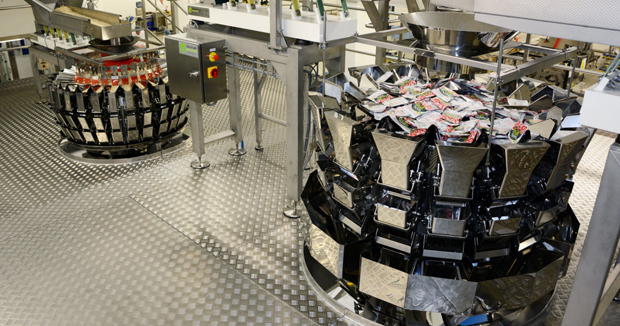

The weighers operate by having a number of hoppers arranged in columns, and each column is fitted with a weighing head. A portion of the product to be weighed is fed into each weigh hopper and the machine’s computer evaluates the optimum combination of hoppers to make up the target weight. These are then discharged together before the hoppers are recharged from above – ready to make the next weighing combination.

This method produces a high level of accuracy when weighing single products, and is used across a wide range of applications from snacks and confectionery to grated cheese, salads, fresh meat and poultry.

Pin-point accuracy

Using larger machines with more weighing heads allows the same principles to be used to provide pin-point accuracy for mix-applications. Each ingredient within a mix can be assigned to a specific section of weighing heads within the machine. They will measure out the required amount of each ingredient and then release them, in most cases simultaneously, via the multihead weigher’s discharge chute into the pack.

Whether it is a pack of mixed sweets, mixed cereals, nut mix, or frozen vegetables, Ishida has a range of specially designed mix weighing solutions with 16, 20, 24, 28 and 32 weighing heads, which enable up to eight different components to be mix-weighed so consistent amounts of each ingredient are included in each portion of the mix.

Such accuracy means brand consistency is maintained and legal requirements when stating percentages of ingredients in a mix can be met. Manufacturers can also control the ratios of products in each portion to manage the quantity of the most expensive ingredients in any mix and to maximise profits.

Another advantage of multihead weighers, particularly when used in mixing applications, is the small factory footprint of the machines. When compared with a production line of individual machines that would be required to do the same job they take up far less valuable floor space. Having one machine instead of several also means maintenance and labour costs are minimised as only one person is needed to monitor the multihead weigher, while several would be needed to oversee a series of machines on the line.

Having all products processed by one weighing machine rather than a line of machines dropping product in sequence also allows products to be mixed effectively – avoiding layering of components if necessary.

A vast range of products with many different characteristics can be handled in mixed weighing. Products could vary from free-flowing components to sticky or fragile components all within same mix. To ensure they are all processed by the weighers at the highest possible speed and efficiency levels, Ishida has developed a wide range of filling systems tailored to each product component characteristic and/or pack type. By adopting a variety of vibration control settings, different contact parts designs, gentle handling options as well as specialist materials and angles, Ishida ensures even the most challenging products pass through the machine at the optimum rate. Where product runs vary, Ishida can also offer optional change contact parts on each section to adapt quickly to many different production challenge requirements.

The attractions of multihead weighers mean Ishida has installed more than 48,000 machines worldwide, including for many leading global food manufacturer customers. Demand for high performance mixed weighing solutions is increasing more than ever and Ishida continues to provide leading innovations in this area.

Tasty multihead solution for Stream Foods

Wide range of applications

- Snacks

- Confectionery

- Grated cheese

- Salads

- Fresh meat

- Poultry

‘Europe’s fastest multihead weighing and packing line with a turnkey installation’ is the claim being made for a solution devised by the project team at Ishida Europe. It includes a 28-head model from its latest generation RV-Series, which is handling 400 packs a minute at fruit snacks manufacturer Stream Foods.

Growing sales of Stream Foods’ Fruit Bowl ranges meant that its existing weighers were struggling to keep up with demand, so it was seeking a solution that would deliver the speed and accuracy it required as well as a rapid return on investment.

“We discussed our requirements with a number of multihead weigher manufacturers and our initial specification was for 200 packs per minute, but Ishida was able to demonstrate that it could offer double this speed with high levels of accuracy,” explains engineering manager Peter Green.

The solution provided by Ishida comprised a 28-head machine working in tandem with a 16-head model. The 28-head machine weighs primary packs ranging from 16–30g of the Fruit Bowl range, and the 16-head machine is counting the packs into five, six, eight, 10,12 and 20 multipacks. This combination is delivering 80 multipacks of the five-pack variant a minute.

As well as quadrupling the speed of the packing operation, accuracy levels have also been greatly improved. “Product giveaway is a cardinal sin and this is something we particularly wanted to address with this new installation,” explains Stream Foods’ factory manager Andy Spall. “Just half a gram overweight in a 20g pack quickly amounts to a huge amount of free product over a single production run. With the Ishida solution, we are constantly within a tiny fraction of the target weight.”

He adds: “Ultimately this line has made us far more efficient and for that reason we anticipate a fast payback on the investment. Furthermore, as well as the speed and accuracy we needed, the line also gives us the flexibility to respond quickly to customer requirements, such as a special promotion, and also to be innovative in our product development. New pack formats are already in the pipeline.”