Promotional Features

How equipment and process innovation can boost sustainability

Sustainability has been a key driver in food and drink packaging long before the Covid-19 pandemic, and will continue to be a focus for most manufacturers and brands well into the future.

With a new plastic packaging tax set to be introduced by the UK Government in April 2022, many packaging manufacturers, food businesses, retailers and brands are continuing to work towards their goals for sustainability and plastic reduction.

When it comes to removing or reducing plastic from the manufacturing process, a company‘s first thoughts usually turn to innovating the packaging of the end-product or changing the material used. However, with sustainability set to be a key driver for change in food packaging long into the future, manufacturers should also consider how to reduce or remove their plastic consumption by taking a closer look at their packaging and processing equipment.

Using innovative processing solutions to reduce plastic

Firstly, producers should think about how to reduce or remove plastic during the initial processing element of their production lines. The number of protein processors offering pre-sliced products is an expanding market in the UK – from sliced cheese and meat to alternative proteins such as plant-based, vegan or vegetarian. Usually, pre-sliced products are interleaved with a wax paper or plastic film after slicing, but before final packaging, allowing for both more sanitary handling and easier product separation.

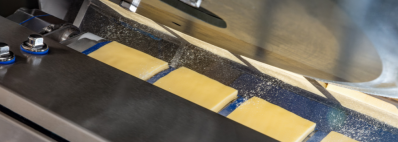

Introducing spray interleaving

The alternative, more sustainable solution is to introduce an innovative spray interleaving system for sliced or highly sticky products. With no requirement for the conventional interleaving film between slices, the consumption of plastic can be reduced at the processing stage to help keep the overall plastic usage to a minimum.

Precision nozzles on the spray system atomise a liquid interleaving medium, which is both odourless and tasteless and can be tailored to meet a producer's individual requirements for the fat content of the product. Removing the additional interleaving film can also help improve the presentation of the product, while the clean separation of the individual slices is still guaranteed.

The liquid is applied evenly to the underside of the slices. The adhesion between the individual slices is therefore reduced but the overall taste, smell and colour of the product itself remain unaffected. The spray interleaving solution can be used for also adding flavour to a product or a coating if the producer desires. This is a common practice already adopted by industries that produce sticky items such as bakery products or sweets.

Also, the need for lengthy set-up procedures is completely eliminated. With conventional paper or plastic interleaving systems, the placement of the paper or plastic typically requires a lengthy set-up time, and can often result in imperfect pack presentation. With liquid spray interleaving, tools such as a rotary knife, anvil or main blade are not required to cut the paper or plastic and the cost for the producer is thus further reduced.

Making your packaging machine work smarter for sustainability

When it comes to the packaging element of any production line, producers should consider how to make their packaging machine work smarter to help reduce plastic packaging waste or consumption. For example, thermoformed packaging is usually a popular choice when producing pre-sliced products.

With thermoformed packs, the nature of the process requires a film trim, but this can be reduced to a minimum by using innovative die technology, which not only helps to reduce the consumption of packaging material but also makes the process more cost-effective.

The edge strips in the thermoforming packaging process ensure the film is guided accurately through the machine and that the filled and finished packs are supported as far as the end of the process. To ensure that a high level of output and pack quality is achieved, the edge strips must have a minimum width. By utilising innovative machine technology – for example, a new, future-proof thermoforming packaging machine – the edge strips required for guiding the film through the machine can be reduced from approximately 19.5mm to 15mm without compromising the packaging procedure.

The seal seam width for thermoformed packs is usually 5mm. By reducing this to 3mm, significant savings can be made in the area of film required to produce the pack. Innovative dies within the packaging machine ensure maximum seal seam quality is achieved.

By combining slicing and packaging equipment to create a portion-to-pack solution, producers can slice and pack sustainably with a minimum giveaway and maximum output.

Innovative labelling

A full-wrap labelling machine can also provide producers with a number of options to innovate their packaging process. Full-wrap labelling solutions can help to reduce the amount of packaging waste. For example, a full-wrap label combined with a board tray offers an end-pack that not only improves recyclability and reduces plastic content but also ensures high stability, stackability and no condensation of the product inside. This type of enhanced packaging solution is perfect for fresh produce, such as fruit and vegetables, to safeguard the packaged product, extend shelf-life and reduce the loss of aroma and nutrients.

A cardboard sleeve can also be replaced by a sleeve applied by a full-wrap labelling solution. Not only does this type of label cost less than a sleeve, but the self-adhesive labels can weigh up to 75% less than an average sleeve, therefore significantly reducing overall pack weight.

As a leading global machinery manufacturer, Multivac is committed to delivering packaging solutions that minimise or eliminate plastic packaging waste and plastic consumption. Through the development of both materials and technology, Multivac is dedicated to helping accelerate the move towards packaging that supports a circular economy.

If you’re interested in learning more, Multivac’s range of solutions will be available to explore at its upcoming Packaging & Processing Discovery Forum: register your place today – https://uk.multivac.com/en/multivac/news-events/events/detail/2021/10/308-oktoberfest/