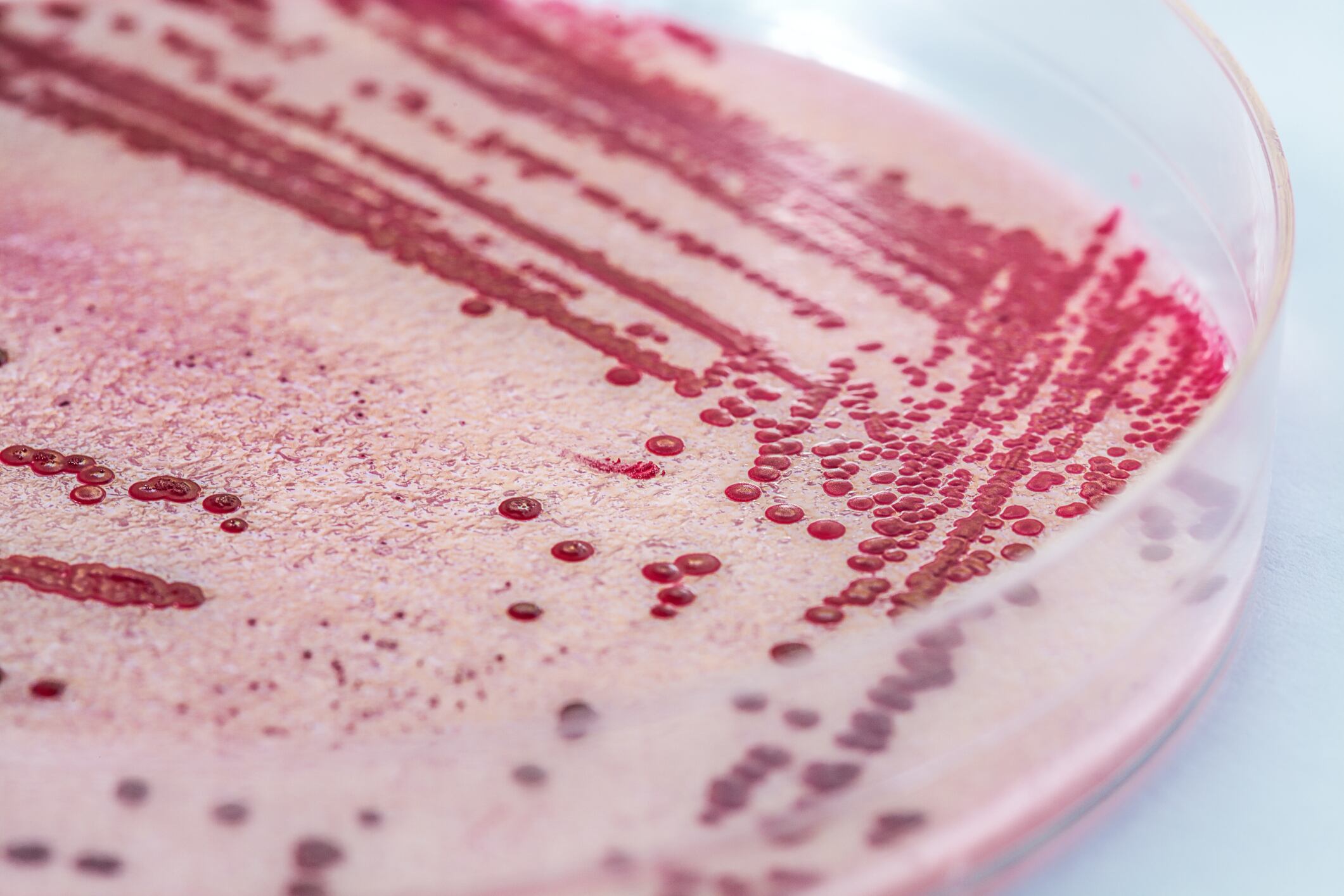

The report sets out key guidance for the management of L. monocytogenes in the food manufacturing industry, which spans planning, testing and response.

Entitled ‘Principles of an environmental monitoring program for the management of listeria monocytogenes’, the CFA report aims to offer SMEs with support in producing an effective strategy.

While raw vegetables, fish and meat are more likely to be contaminated with the pathogen, it can also be found in ready-to-eat food, refrigerated goods and processed cooked food. As a result, the creation of an environmental monitoring programme is essential in any manufacturer’s toolkit.

Developing an appropriate listeria strategy

An environmental monitoring programme should be supported through visual inspections, swabbing at risk areas using ATP monitors to judge cleanliness and sampling plans that should be reviewed annually. The locations in which these strategies are employed should change regularly when strains of listeria are not detected to ensure all areas are safe.

The CFA guidance also specifies a list of considerations that must be acknowledged while establishing an environmental sampling programme. The report states that such a programme cannot be generic due to variations in size, complexity and risk within food manufacturing environments, and therefore a tailored approach must be developed in-house.

The considerations that must be taken into account during the design of this approach include the type of sample that is being taken, the location and number of samples, the frequency of sampling, the tools and techniques in use, and the level of training given to the individual taking the sample.

The analytical methods used to identify L. monocytogenes must also be suitable for the setting, while all listeria data should be stored, with a focus on this strain as it dangerous to humans. The trends identified by the analysis and data storage should then be assessed weekly, so that any outbreaks can be prevented and managed.

On the issue of finding listeria strains, the CFA reaffirms that it is not uncommon for them to be found in a processing environment and that enforcement agencies do not need to be informed in every case. However, an appropriate plan should be established that allows the situation to be managed.

Such a plan should include a review of all data leading up to an outbreak, allowing for investigations to be targeted and the source of contamination to be more easily identified. Once this has been established, the appropriate action can be determined based on the level of contamination and the risk of products being contaminated.

Additional samples can then be taken to trace the source of the listeria, depending on the risk of recontamination. Otherwise, additional cleaning and testing of a product can be required.

In other news, Denise Rion of the BFFF looks at the guidance around Listeria in the UK.