Mycoprotein will be made available though the newly set up Marlow Ingredients, firstly in Europe and then internationally.

Marco Bertacca, Marlow Foods chief executive, said: “We recognise the urgent need for humanity to eat more sustainably. By making our mycoprotein available to others, Marlow Ingredients will play a pivotal role in helping us achieve one of our missions – to tackle climate change by making great tasting food.”

Mycoprotein in foodservice

Arguably one of the most recognised meat-alternative brands, Quorn has seen success in the foodservice sector through partnerships with KFC across Europe, Greggs in the UK and Quick restaurants in Belgium.

Marlow’s decision to extend the reach of its Mycoprotein comes on the back of the UN Intergovernmental Panel on Climate Change Synthesis Report, which called an urgent shift towards sustainable diets to “secure a liveable future for all”.

“There’s huge potential for our mycoprotein,” Bertacca added. “There’s exciting research happening into its ability to create more sustainable versions of other applications, such as dairy alternatives. Marlow Ingredients is initially focussed on building partnerships with food manufacturers, but the potential for the future is very exciting.”

Net zero mission

The launch forms part of Marlow Food’s mission to become a net positive business by 2030 and, in that year, provide eight billion servings of mycoprotein – one for every person on the planet.

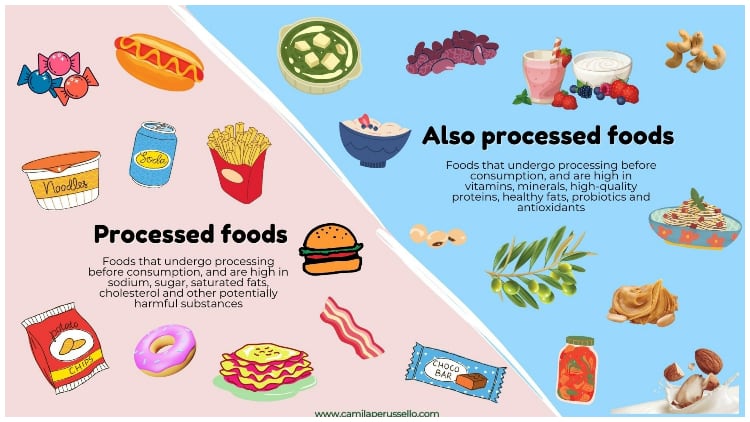

In other sustainability news, converting food waste into protein could help the global hunger crisis, according to new research from King’s College London.

The paper, published in the journal Green Chemistry, argued that technologies such as fermentation and harvesting insects grown on waste food could provide three times the amount of protein the average person needs to feed every person in the world, every day.

Meanwhile, Katrina Anderson, associate director and Sian Edmonds, senior associate at Osborne Clarke, discussed five stages to navigate when developing and commercialising a new alternative protein product.