The first steps

The first step that WRAP always advocates for businesses is to begin by looking at its own operations and adopt a Target, Measure, Act approach to identifying where food is being wasted and why it’s happening at certain stages of the operations process, which is key to minimising overall waste.

Even though this will be a KPI for many businesses, it’s often still the case that some businesses cannot identify exactly how much food waste and surplus is produced or where along the line it happens. However, this is a fundamental aspect of reducing overall waste output and should be the first port of call for all manufacturers.

Collaboration is key

Once a manufacturer has pinpointed where and why the waste is happening, they should set targets to reduce and have action plans in place. They should then consider working across the whole supply chain with their customers and primary suppliers. Manufacturers should have ‘whole chain projects’ in place, whereby they have strong relationships with their partners throughout the farm to fork journey and can each identify areas of potential and current waste throughout operations. The concept of a ‘whole chain project’ pertains to the relationships in place at every stage of the supply chain.

Building these relationships can allow the manufacturer to explore areas that may be leading to waste, throughout the entire life span of food products. Are primary suppliers being left with waste or a surplus? Are retailers providing accurate information/forecasts? Do companies need to improve packaging and labelling to help the end consumer reduce waste in the home – e.g., follow best practice guidance for best before dates and storage advice.

Fundamentally, the closer the manufacturer can work with its suppliers and retail customers, the bigger the impact it can have on the end consumer, which we know is where the greatest amount of food waste comes from. Recognising that they have this responsibility to the end consumer is vital to the process.

Food waste and surplus

If a manufacturer does end up with overstock of a product and has a surplus, then it will need an outlet to distribute. If it doesn’t have a secondary market, then this is when re-distribution to charities comes into play.

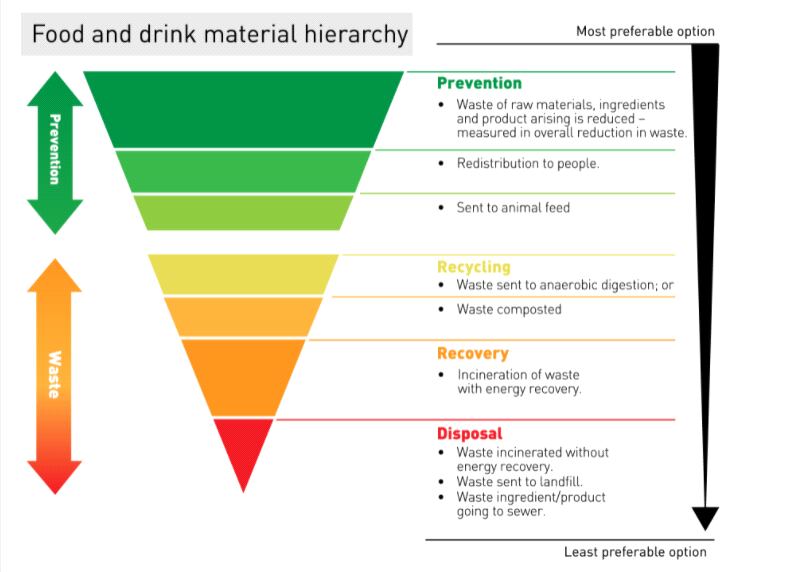

The UK is held up as an example of best practice on food waste prevention across the world, but there does continue to be surplus and waste across all industries, including manufacturing. The UK has adopted the International Food Loss and Waste Standard definition of food waste and surplus and the hierarchy when it comes to preferred routes for food that could not be sold as intended.

The UK food waste hierarchy below outlines the preferred options:

WRAP resources

WRAP has produced a suite of materials that contain all the information you need to help increase the redistribution of surplus food. Whole chain food waste reduction plans (WCPs) are also a key goal for WRAP’s Food Waste Reduction Roadmap, and WRAP encourages businesses to participate in these WCP’s to take joint actions that reduce farm to fork food waste. The third progress report on the Food Waste Reduction Roadmap was published last month and some key highlights from the report included:

- 251,000 tonnes of food worth £365 million saved from waste

- 670,000 tonnes of GHG emissions potentially avoided

- 145 million meals redistributed

Manufacturer waste prevention case studies

Most of the UK’s largest manufacturers are signed up to the Food Waste Reduction Roadmap and over 40 of them are now following best practice and publishing their food waste data and actions in the form of case studies.

These case studies highlight examples of waste reduction in manufacturing operations and increases in the amount of surplus food redistributed to charities that would otherwise have gone to waste, all supported by data. There are also three published case studies of Whole Chain Plan projects led by retailers Sainsbury’s, Waitrose and Abel&Cole working with their supply base.

These projects were facilitated by WRAP and are based on the five-stage process below, as well as being supported by a WCP toolkit.

- Where is the waste?

- Why is waste occurring?

- What solutions may prevent waste from occurring?

- Implement and measure the success of a trial

- Review and roll-out

As well as the manufacturer and retailer these projects involved the primary producer, with on farm data and insight being gathered for the first time.

Some of the findings were that waste can be reduced and savings made by reviewing varieties and product specifications at the growing/harvesting stage, exploring valorisation options for unsuitable produce with other suppliers, looking at pack sizes and handling practices in store, and by conforming to best practice labelling to help consumers reduce waste in the home.

The Whole Chain Plan provided a rare opportunity for the whole supply chain to come together and discuss how they can move from what was already minimal food waste to zero food waste and is a shining example of the steps manufacturers and retailers can take reduce waste further.