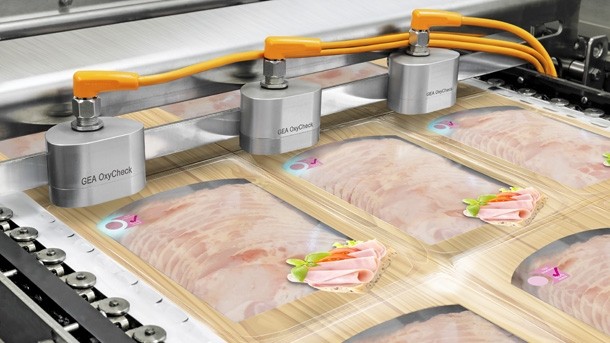

Non-invasive test of modified atmosphere packs is introduced

GEA’s OxyCheck system is claimed to be world’s first non-invasive oxygen measurement system for MAP, which provides 100% quality control by checking the oxygen content and seal integrity of every single food pack.

What makes this approach innovative is that each MAP pack is non-invasively inspected after sealing on one of GEA’s thermoformers instead of having to be damaged by inserting a needle to measure the composition of MAP gases inside packs, as was the norm until now.

This is said to make costly spot checks obsolete, as films and seals remain intact, and there is no loss of product or materials.

Make costly spot checks obsolete

“For us, what consumers want is just as important as what retailers want, which is products with a longer shelf-life. Both have a bearing on which hygiene and quality requirements must be met, which in turn is what manufacturers must fulfil,” said Volker Sassmannshausen, senior product manager at GEA.

“All three target groups benefit from GEA OxyCheck, because the system helps to ensure that food reaches consumers in perfect condition.”

Sassmannshausen told Food Manufacture that GEA was also working on the development of a version of the test that could be used by retailers to confirm the continued integrity of MAP packs.

Today, more than half of all retail fresh food – meat, fish, poultry, fruit and vegetables, confectionery and baked goods as well as dairy products – is packaged in a modified atmosphere, claimed GEA. OxyCheck works by monitoring the residual oxygen content of packs during production.

Monitoring the residual oxygen content

The technology uses a sensor spot made of a polystyrene-based fluorescent dye that is printed on the inside of the film. Similar to an indicator strip, the wavelength of the dye changes dependent on the oxygen content inside the pack.

Sensors on the GEA PowerPak thermoformer activate this sensor spot and then take a reading. The oxygen concentration is calculated based on the light emitted and the temperature.

Previously, spot checks were carried out to measure the oxygen content in MAP – which meant that less than 0.5% of the packs were typically tested, and packs would be invasively tested with a probe.

When packs did not meet specifications they, together with preceding ones, would be destroyed. In contrast, the GEA OxyCheck process can check each product.