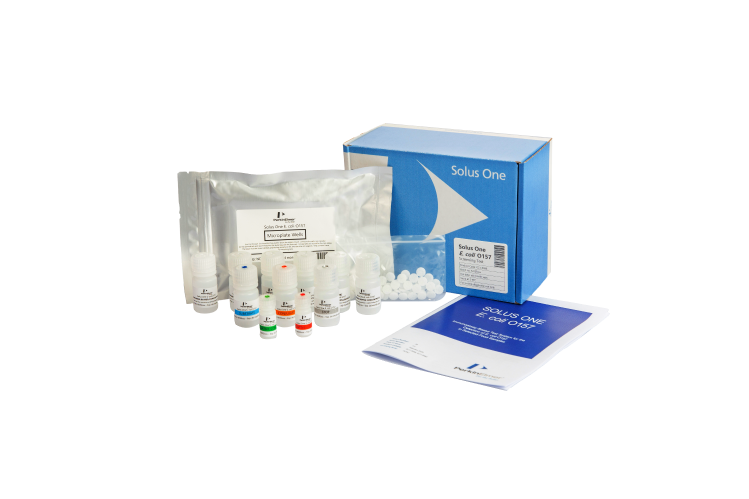

The Solus One E.coli O157 Pathogen Detection Assay can process up to 192 tests per run. It is designed to be as user-friendly as possible, with the instrument, kits and methods involved require less training than traditional approaches for lab technicians.

This allows technicians to “set it and forget it” for two hours, PerkinElmer claimed, freeing up their time to conduct other work such as running another automated protocol to maximise throughput.

Support for high volume testing

The system is designed for customers who receive a high volume of food samples daily and need a highly sensitive, cost effective assay.

Greg Sears, vice president and general manager of food at PerkinElmer, said: “E. coli O157 is important and requires scientific expertise to provide solutions that food processors and contract labs can trust.

“With our new high throughput offering, we can help food processors stay ahead of the constant E. coli testing cycle by streamlining their testing workflows and increasing productivity while helping to protect consumer safety in the global food chain.”

E.coli related illness

Escherichia coli (E. coli) bacteria are commonly found as part of normal gut flora of humans and animals. While most strains are harmless to people, some strains – including the most common E. coli O157 – produce toxins that can cause intestinal illness.

In 2019, shiga-toxin-producing E.coli was identified as the third most common cause of foodborne disease, with campylobacter strains first and strains of salmonella second, according to the EU One Health 2018 Zoonoses Report.

Meanwhile, the vetting process for new products leaving food and drink factories has been forced to rapidly update itself in the face of the new normal created by the COVID-19 pandemic. From using smart technology to adapting to smaller spaces, we look at the latest advances in detection and inspection at the production plant.