Health, flexitarianism and snacking opportunities are big drivers of innovation in sausages and burgers, but improving quality and reducing waste remain the focus of developments in food forming and casings.

During the height of last year’s spectacular summer, Kantar Worldpanel highlighted steady growth in burger sales, up 9.1% over the last five years to 2018, while sausages made a comeback after a dip three years ago, boosting sales by £27m to £672m between 2017 and 2018.

This marks a turnaround for the categories that have been subject to significant pressures in previous years. Key to this survival in such a competitive market from a manufacturer’s point of view is consistent quality, reduced wastage and improved efficiency – achieved by having the right equipment.

Using the right bowl-cutting, grinding and mixing technology, with capability to automatically adjust fat content as the meat is being processed, is crucial for manufacturers producing high-quality burgers or sausages, says Interfood.

The company’s Preparation Division supplies a full range of mixers, grinders and emulsifiers from German manufacturers K&G Wetter and Inotec, available as stand-alone units or for integration into automated lines.

Inotec offers fat analysis across each batch and supplies link-cutters as well as mixers, while the K&G Wetter range of grinders covers applications of all scales from straight grinding to mixing and grinding and frozen block grinding.

“Burgers and sausages continue to be a staple of the UK’s diet,” says James Radcliffe, manager of Interfood’s Preparation Division. “Consumers’ focus on a healthier lifestyle has led to the development of a whole range of new innovations in this area, with the focus on fat content becoming even more important as getting the fat levels right on trims and cuts from animals that have been bred to be leaner can be more difficult.

“It is also a very competitive market so having the product stand out on the supermarket shelf is crucial. By using grinders to generate a clearly defined ground meat appearance, burger producers can significantly improve the look of the product in the pack.”

High-quality products

For manufacturers creating high-quality products, Multivac recommends its Risco line of fillers. “Risco’s patented, non-compression pump technology helps preserve the protein structure and particle definition of the diverse ingredients used in sausage and burger production,” says Liam Smith, processing product manager at Multivac UK.

“This helps the producer ensure the ingredients are the centrepiece and maintain a clean-label product. The non-compression meat pump technology produces the highest quality product output, making it ideal for the artisan, premium market demanded in the UK.”

A recent addition to Risco’s range, the RS261 Dual Horn sausage linking system, increases output, efficiency and flexibility across different product types and lengths, he says.

“The machine is a highly flexible system that offers benefits to all sausage and casing types. The patented non-compressive vacuum pump technology and natural casing feature drive this new machine towards the British, coarse-ground, premium sausage market on an industrial scale.”

Multivac says live trials have indicated output improved by as much as 50% for manufacturers using the new system, with the best results achieved with natural casings by dramatically reducing dwell time between production shifts.

The RS261 linking system can be integrated into production lines, alongside grinders, mixers and automated transportation, and will be on display at IFFA in Frankfurt, Germany in May.

Meanwhile, Dublin-based McDonnells (Queen Street) has launched a new Patty-O-Matic Eazy Slider burger maker, targeting manufacturers in the UK and Ireland that are aiming to create products with a more bespoke or artisan appearance.

“The Patty-O-Matic produces up to 60 portions a minute, giving a handmade appearance to the burger,” says John Gallagher, business development manager at McDonnells. “It is quick, easy to use, and simple to clean, with no need to pre-weigh portions to form burgers. It can produce multiple burgers at a time.

“It is an extremely versatile forming and portioning burger maker. Forming plates can be customised to any shape: square, round, oval, home-style, even meatball.”

Air Products’ food division Freshline lays claim to improved efficiency and quality, and potential cost savings, through its LIN-IS technology replacing CO2 with liquid nitrogen to control the temperature of meat during forming.

CO2 replacement

While the technology has been available to UK burger, sausage and other formed food manufacturers for 12 years, interest was reignited last year due to the well-publicised shortage of CO2.

“The food industry is probably one of our biggest gas users,” says Neil Hansford, applications manager at Freshline. “We’ve got hundreds of users taking anything from a small gas cylinder to freezer tunnels or the LIN-IS system. Any food substance you find in a supermarket, a large proportion of it has got gases in it or a liquefied gas has been used to cool it or freeze it.”

Trialling the flexitarian trend

No longer a fad, flexitarianism is increasingly entering the mainstream market – from Marks & Spencer launching its new Plant Kitchen range to pork processor Finnebrogue announcing a new £3m vegan and vegetarian factory.

Already producing vegetarian and vegan products for three years, Northern Ireland firm Finnebrogue expects its new factory to turn over £30m a year.

“Health is becoming a huge driver in developing certain target markets in the production of sausages and burgers,” says Liam Smith, processing product manager at Multivac UK. “Consumers are seeking alternatives for pork and beef, substituting them with poultry, beans, pulses and vegetables.”

A recent revamp of Multivac’s Swindon site, adding a fully temperature-controlled test unit, has sparked interest among manufacturers embracing the flexitarian trend, with its Risco vacuum fillers and sausage systems proving popular.

“The trials on the Risco processing equipment have been successful in producing sausages, balls and other shapes with various core ingredients, including meat and meat-free alternatives, while achieving a high-quality taste and aesthetic,” says Smith.

Hansford says that, while CO2 is a by-product of fertiliser production in the UK – and thus subject to fluctuating availability – liquid nitrogen is formed naturally and unlimited in supply.

Liquid nitrogen has further advantages over CO2, he adds. Unlike CO2, which turns into a snow and requires a longer mixing and cooling time to combine with dry product, liquid nitrogen can be injected at a colder temperature and its liquid form makes it easier to mix.

“The mix times can be quicker, the amount of gas you use is less and you get a much more homogeneous temperature across the product,” says Hansford. “You get a better-finished food product, less waste, less tearing of edges and a much more repeatable process.”

Freshline’s LIN-IS system is designed to significantly reduce wastage in major plants producing, for example, thousands of burgers a minute, where tearing or uneven forming can result in a high level of wastage, he says. “The cooling resolves that so you get the same texture, repeatable product, repeatable forming and reduced waste.”

While most frequently used with formed meat products, the technology has many other food applications, such as producing extruded ropes of cheese for stuffed crust pizzas.

Steve Naylor, manager of Interfood’s Cooking & Cooling/Pasteurisation Division, stresses the importance of exact weight portioning during burger forming to minimise giveaway. Gentle two-dimensional and three-dimensional forming avoids the consistency becoming too dense, he explains.

The Alco range of forming machines, supplied by Interfood, are said to offer easy use, with the capacity to rapidly change form plates to accommodate different products, while reduced dead space minimises waste. Three belt widths are available in 250, 400 and 600mm, with all process parameters adjustable to specific product requirements.

Another model aimed at offering manufacturers greater efficiency in terms of reduced labour and wastage and greater flexibility is Cabinplant’s Automatic Sausage Depositor.

Taking the intensive labour out of sausage packing, the Sausage Depositor can be used for sausages, cocktail sausages, meatballs and other formed meat products. Capable of handling multiple layers of products and various formats, it uses gentle vibration to avoid product damage on the conveyor system, while it suits rapid product changeover, minimising downtime.

The case for casings

Cost savings can also be made by using the right casings, according to Lee Hamilton, UK & Ireland sales director at Devro. Manufacturers using its collagen casings can cut their labour requirements and enable machines to run at faster production speeds.

“Sausage manufacturers are under increasing pressure to keep their products competitive commercially,” he says. “Collagen allows the manufacturer to produce a sausage to the exact size they want with minimum waste. This is achieved without detracting from quality, enhancing the bite – and all with market-leading traceability from a UK manufacturer.”

For Powters Sausages, gaining efficiencies is a focus, “but never at the expense of the quality or integrity of our product”, says managing director Tristan Powter.

“As a small to medium-sized business focusing on artisan production methods, our priority isn’t keeping production costs down, but is more geared towards achieving value for the consumer and transparency in our production. We focus our efforts on encouraging the consumer to choose value over price.”

Powters acknowledges health as a recent focus of innovation in the sausage category and, in response, has launched the Skinny Pig, a low-fat, gluten-free sausage. However, the company believes taste, quality and value remain the key drivers of consumer purchasing habits.

“Another key driver is familiarity,” he says. “The vast majority of consumers purchasing sausages or burgers are not looking for a radical reinvention of the product itself, but for a product they can trust, which has honest provenance, is tasty, and represents value.”

Meeting market trends

Devro says it can offer casings that span market trends, from cocktail and traditional sausages to premium, diet and flexitarian lines. “The cooked sausage sector is continuing to show growth as it captures consumer trending towards convenience foods,” says Hamilton. “Our Devro bovine and porcine collagen casing ranges were specifically developed for these applications.

“The premium sausage sector also continues to perform strongly. The Devro Select-F range is now well established in the premium sector, with more than 300 customers converting from natural casings.”

Uptake of the Select-F range is strong among both award-winning butchers and premium supermarket ranges. “The Devro Select range is now used by the number-one performing premium sausage brand in the country,” says Hamilton.

“The efficiencies associated with Devro casings allow the manufacturer to save on costs and if wanting to, invest this saving back into the sausage to increase the meat or protein content or reduce salt to meet the current health drivers in our industry,” says Hamilton.

Meeting the demand for traceability and clean-labelling, the company uses only UK and Irish-approved hides for its bovine collagen range and also offers a pork collagen line.

Devro also offers casings for popular Continental-style sausages or US-style beef sticks, with its Stix range.

Hydrosol, which supplies alginate casings in two variants suitable for animal protein, halal, kosher, vegetarian or vegan sausages, is also targeting rising demand for snacking products. It says its SmartCasings offer advantages over conventional styles, costing less to manufacture and store as they come in powder form.

For snacking products such as hot dogs, currywurst or salami stick, whether meat or plant-based, SmartCasings involve application of a liquid alginate layer to the sausage. Hardened into a firm structure in a calcium bath, the strong and edible casing gives sausages a crisp bite, claims the firm.

Also suitable for fresh bratwurst, raw sausage and scalded sausage, the casings are said to be highly tear-resistant.

“Scalded sausages are a particular challenge, as they are exposed to damp heat, both during manufacture and later during preparation,” says Florian Bark, product manager at Hydrosol.

“So, the casing needs to be not just tear-resistant, but also adhere to the sausage mass after cooking. To make sure it does, the sausages are cooked not by hanging in steam, but instead in a water bath using a special technique.”

Casings get the colourful treatment

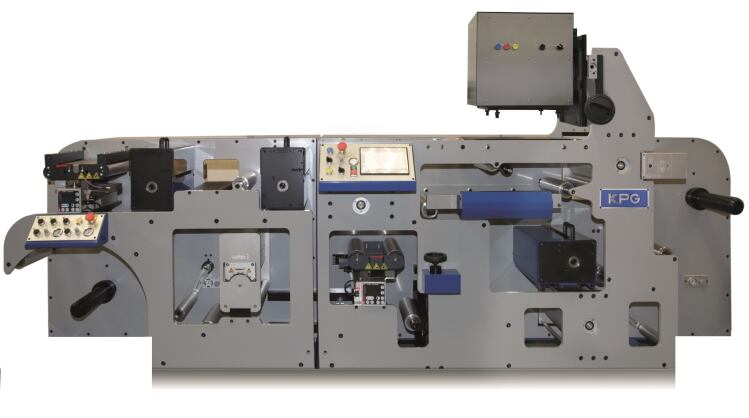

Casing providers Resino Trykfarver and KPG Europe have combined to create a digital system for printing casings in full colour, in an attempt to capitalise on the potential benefits of being able to access short-run production capability, including instant image change with virtually no material waste or downtime.

Set to be unveiled at IFFA in May, the new system is a culmination of two years’ work by the two companies, which included the development and extensive trials.

Resino was responsible for finalising the development programme, adapting its flexographic UV-curing ink technology for printing artificial casings, into an inkjet applicable variant called the Resucat 220 series.

Resino says that casings printed with this inkjet variant can be treated in the conventional way in terms of shirring, filling and autoclave processing. The Resucat 220 series is also low migration and low odour, and has no need for primer or overprint varnish.

In designing the new digital system, KPG says it has been able to utilise its experience in supplying dual-pass flexo casing presses. A spokesman says: “With PDF handling, instant data changes, choice of print resolution and production speeds of 600x600dpi and up to 100m/min depending on design, short-runs are now a reality for casing printers.”

Optional features for the system include fully automatic production and a chilled central impression drum version.