The business, which sells direct to consumers, has turned a once manual operation into a high-speed production line capable of handling the current Christmas rush and preparing for international expansion with the help of Made Smarter.

Made Smarter is a UK Government-backed programme designed to help manufacturing SMEs adopt digital technologies and develop the leadership and skills needed to drive sustainable growth.

Founder Scott Harasyn launched Bubble Panda from his kitchen table in 2020 during the Covid-19 pandemic and now operates from an 8,000 sq ft facility producing thousands of flavour combinations.

Over the last two years Made Smarter said it has supported Bubble Panda to create a digital roadmap, embed a digital culture, and access a £20,000 grant towards a RotoFill reel-fed filling and sealing machine. The business now also runs two fully optimised production lines.

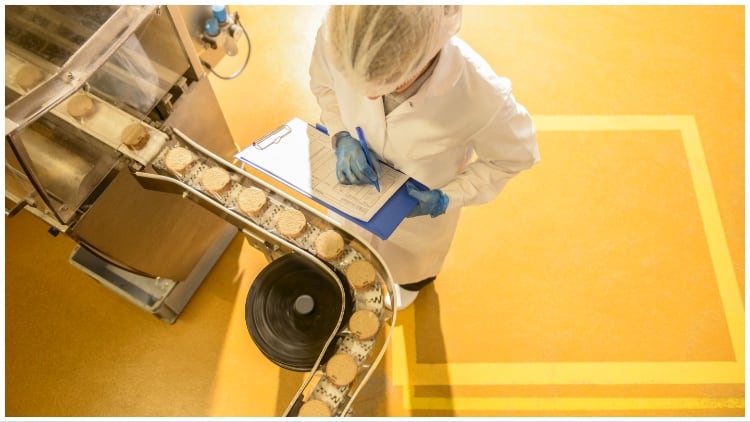

The result is that production time has dropped by more than 80%, changeover downtime has fallen by 90% and overall output has tripled. Automation has allowed staff to move into quality control, data analysis and process optimisation roles, while waste has fallen and sustainability performance has improved.

Bubble Panda has been able to advance new product ideas and partnerships, including a collaboration with Derbyshire-based confectioner Swizzels.

Harasyn said Bubble Panda would not have coped with this year’s seasonal spike without the digital overhaul.

“Without automation we would never have been able to keep up,” he commented. “Made Smarter has completely transformed how we operate. The support, the partnerships, and the technology have given us the confidence and capacity to grow, innovate and expand internationally.”

Made Smarter introduced Bubble Panda to NERIC (the Northern Engineering and Robotics Innovation Centre), based at the University of Salford.

Its technology consultants restored a broken taping machine and tripled its output overnight, designed and tested a dual-robot pick-and-place cell capable of handling tubs at four-second cycles, integrated advanced vision systems for seal inspection, accuracy and repeatability, and mapped out future automation options across production.

Donna Edwards, managing director of the Made Smarter North West Adoption Programme, said: “Bubble Panda is the perfect example of how a small manufacturer can take bold steps with the right support behind them. Scott recognised that digital transformation was essential, engaged with our experts and the results speak for themselves.”

Tabs Khojani, business development Manager at NERIC, added: “It’s fantastic to see the outcome of such a strong partnership between NERIC and Made Smarter to help SMEs unlock the funding, support and technology they need to grow. We share the view that robotics and automation are essential for the future of UK manufacturing. Bubble Panda is a brilliant example of what happens when manufacturers tap into the support available across the region.”

Since its launch in the North West, Made Smarter has helped more than 2,300 manufacturers, delivering over 400 technology projects that are forecast to create almost 2,000 new jobs, upskill almost 3,500 existing roles, and add £287 million to the regional economy.