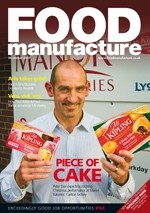

To the manor born - the humble pie

Peter dee, bakery general manager, manor bakeries

I've been on site for just 11 weeks and I've come from outside the industry, so it's been a steep learning curve coming to what is the biggest bakery in Europe.

I'm a chemical engineer by background, although having studied at Loughborough University, I started my career as a Unilever management trainee at Quest International, then its fragrance and flavours division. I had exposure to brands such as Batchelors and Van den Bergh Foods there as a production manager in the flavours business.

My last role was European supply chain director at Uniqema, which makes specialist chemicals from natural oils and fats. I was keen to go downstream to fast moving consumer goods manufacturing for my current role.

There are opportunities to bring skills from the specialist chemicals sector into this position. For example, where I came from was regarded as world class in terms of safety procedures and lean management techniques. My background in supply chain management was also key to understanding how raw material supply works and how the sales process affects production.

One of the most challenging aspects of this role is that most of the management team is relatively new. It's a key test to provide a leadership programme to bring the team together as a whole.

Another major challenge is joining at the beginning of the Christmas programme and having to deliver on it and maintain our service levels to our customers. We believe this Christmas will be our biggest ever and we're in for a record-breaking production run.

We start building up production from August, with the festive period being peak time for us. Output is expected to be 100M mince pies alone, both under the Mr Kipling brand and under retailers' own labels, which represent 30% of our total production. Trifle sponges are also a significant volume driver for us over Christmas.

Our products also include chocolate rolls, Viennese whirls, sandwich sponges and fondant fancies.

We deliver all our products to Manor Bakeries' national distribution centre in Rugby and from there it goes out to retailers and, ultimately consumers.

The factory makes 250 stock keeping units and has 15 lines, three having been transferred when our Eastleigh site in Hampshire closed in 2005. Since then, we've invested £27M in the transfer and in new equipment.

Premier Foods took over ownership of the business in April and moved relatively quickly. The bakery has obviously become part of the integration process that is already well under way. We recently had a site visit from Robert Schofield, chief executive of Premier Foods, which was well-received.

One of the programmes we're rolling out at the moment is SAP Fusion - the name for Premier Foods' business resource planning system. We've installed some systems and the first phase of implementation, the order to cash, demand planning and finance modules, will be during next year. The aim is to move the whole factory on to it by 2009. We've already held educational events. Fortunately there are a reasonable amount of people who have experience of implementing SAP technology already and a support team is already on site.

We've also just installed barcoding and radio frequency identification, providing visibility and flexibility for dispatch and packaging and ensuring consistency between us and Manor Bakeries' distribution centre in Rugby. There have been significant benefits in terms of order accuracy and it's our intention to extend this throughout the factory from the start to the finish of the production process. There will be no need for hand-held scanners; we'll be able to record when products go on and come off the line automatically. It will significantly reduce paperwork and the time taken up with moving materials from a to b.

In health and safety, there have been incidents of slips, trips and falls and we're cracking down on that. We've installed anti-slip strips on steps and we have a stringent 'sort it or report it' policy. We have an in-house safety team that has been in place for 14 months.

Environmentally, Premier Foods' bakery business has been hit by significant rises in raw material costs, so we're on a significant drive to cut waste and drive efficiency. We have a series of monthly key performance indicators that run on a red, amber, green traffic light system based on the quantities of waste produced.

Manor Bakeries has a major focus on its environmental credentials and aims to generate positive energy credits and meet the government's 2010 targets for carbon dioxide reduction. This factory has reduced gas, electricity and water consumption by 20% in the past 12 months. Air and water are our biggest loss areas, especially through leaks. Where workers spot these, they take a tag and put it on the leak area so someone can check it and deal with it. We operate a league table across all our lines to show which is performing the best.

We used to have three air compressors on site and now we're only on one. We're reducing our water use by reusing water from our effluent treatment system.

People are another important focus for the business and there has been a lot of re-organisation in the bakery in the past couple of years in relation to streamlining the management structure. We have taken out two layers of managers and implemented first line bosses.

We have an ongoing programme of multi-skilling and training needs analysis. We're aiming to train up 54 engineers in-house by financial year end. This is a pilot project with a view to implementing personal development plans for all 850 of our weekly staff.

We're also looking to introduce one or more technical operators per line in the next few years. We have opened a new learning centre by our canteen in partnership with the unions, which we hope to use to upskill and train people in basic skills.

On personal development, we also have our Your Shout programme, supported by a free newsletter, which has been created to give workers a say in the running of the factory. We're addressing the issues that came out of an attitude survey at the start of the year and following that up with a review in January. We will continue to do this to improve overall performance. There's also our Gems scheme to award employees who go the extra mile.

We're not complacent. We recognise we have a lot further to go. That's why the engagement of the workforce is absolutely essential.

Interview by rod addy

FACTORY FACTS

Location: Manor Bakeries, Fish Dam Lane, Carlton, Barnsley, South Yorkshire, S71 3HQ. Tel: 01226 286191

Size: 40,000m2

Output: 145M packets per year

Employees: 920 permanent staff, plus 230 agency workers at peak periods

Number of production lines: 15

Annual growth: 5% (vol.)

Products: cakes and pies under the Mr Kipling, Lyons and Cadbury's brands and retailers' own labels

PERSONAL

Name: Peter Dee

Age: 46

Career highlights: "The successful European implementation of SAP at Unichema Chemicals. That's very important for us here, because we're just beginning that journey."

Domestics: "I live in the Wirral in Merseyside, but I am in the process of getting an apartment near the bakery for during the week. I'm married with three children: two boys and a girl.

Outside work: "I play football and tennis and run 10km races and half marathons. I have entered the London Marathon for next year."