Achieve robust, defensible mineral oil quantitation with reduced uncertainty.

Mineral oil hydrocarbons (MOH) are primarily derived from crude oil, but MOSH fractions routinely include petrogenic, biogenic, and synthetic hydrocarbons, while MOAH fractions may contain process-derived aromatics not exclusively from mineral oil sources. In routine practice, MOH are typically divided into MOSH (mineral oil saturated hydrocarbons) and MOAH (mineral oil aromatic hydrocarbons). These may enter food via multiple pathways: processing aids, environmental background, transport, lubricants, or migration from packaging materials.

As the food sector has moved toward lower tolerances and more rigorous risk assessment, laboratories have faced the same core question for more than a decade: how do you measure something that is, by nature, a complex mixture – without being misled by other complex mixtures already present in food? The analytical history of MOSH/MOAH is, in many ways, the story of solving that problem.

The early challenge: complex mixtures don’t behave like ‘normal‘ analytes

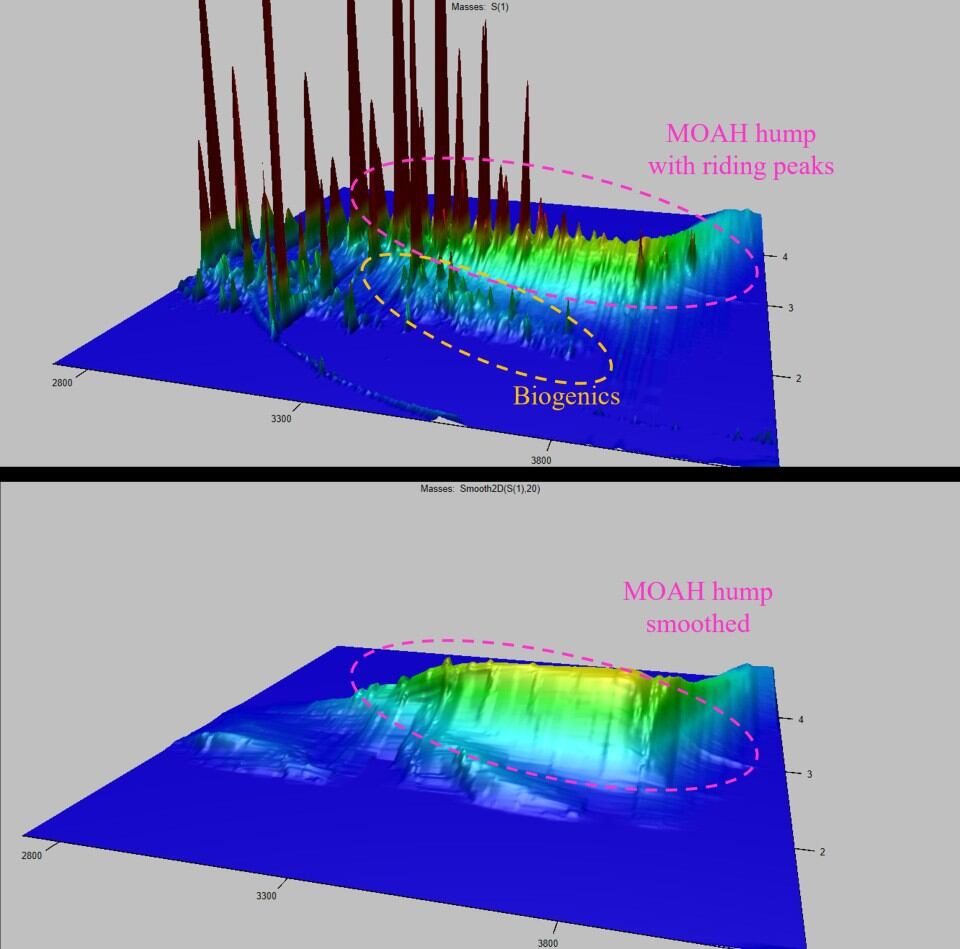

Classic residue methods were built around the idea that ‘analytes resolve into peaks’. MOSH/MOAH rarely cooperate. Many samples produce broad unresolved complex mixture (UCM) signals – the familiar ‘humps’ – rather than tidy peak patterns. Those humps can be real mineral oil, but they can also be biogenic hydrocarbons and other naturally occurring components that behave similarly under gas chromatography. This is particularly true in matrices such as vegetable oils, fats, spices and other hydrocarbon-rich foods.

That reality shaped the first major era of MOSH/MOAH testing: methods were designed to isolate fractions first, then quantify them as best as possible with a robust detector.

LC-GC-FID becomes the workhorse

Over time, LC fractionation coupled to GC-FID became the backbone of routine MOSH/MOAH analysis. Conceptually, it is elegant: separate MOSH and MOAH on liquid chromatography, then quantify each fraction on GC using FID, which responds relatively uniformly to hydrocarbons and supports robust quantitation for ‘mixture-like‘ signals.

This LC-GC-FID approach remains highly valuable for screening and monitoring because it is familiar, relatively standardised, and throughput-friendly. But as laboratories pushed into more challenging matrices and lower detection limits, constraints became increasingly visible:

- Specificity is limited. FID is excellent for quantitation, but it cannot confirm identity.

- False positives can occur when non-mineral hydrocarbons contribute signal in MOSH/MOAH regions. Key interference sources include: systematic MOSH overestimation from polyolefin oligomers (POSH), MOAH overestimation from olefinic/aromatic processing artifacts, and incomplete LC separation particularly in the C16-C25 range.

- Carry-over between fractions (for example, MOSH bleeding into the MOAH fraction) and co-elution can distort reported values.

- The outputs can be difficult to interpret at the decision margin, where the difference between compliant/non-compliant may be small.

These issues did not make LC-GC-FID obsolete – instead, they clarified where the method benefits from complementary confirmation.

The regulatory and guidance era: clearer expectations, higher stakes

As attention increased, so did the push toward more consistent sampling, reporting, and risk interpretation. Guidance documents and scientific opinions helped align what to measure and how to interpret it, particularly for MOAH, where toxicological concern is linked to aromaticity and structural class. Recent guidance has also encouraged laboratories to provide better separation and reporting that supports risk assessment, rather than only total ‘hump area’.

In parallel, standardisation efforts have continued to mature. For many labs, this has had a practical effect: MOSH/MOAH results must be defensible, especially in complex foods and in borderline cases where overcalling contamination can have real commercial consequences.

The next step: adding confirmation without breaking routine workflows

Once the limitations of single-detector screening were well-understood, the analytical question shifted from “How do we quantify humps?” to “How do we confirm what the hump contains?”

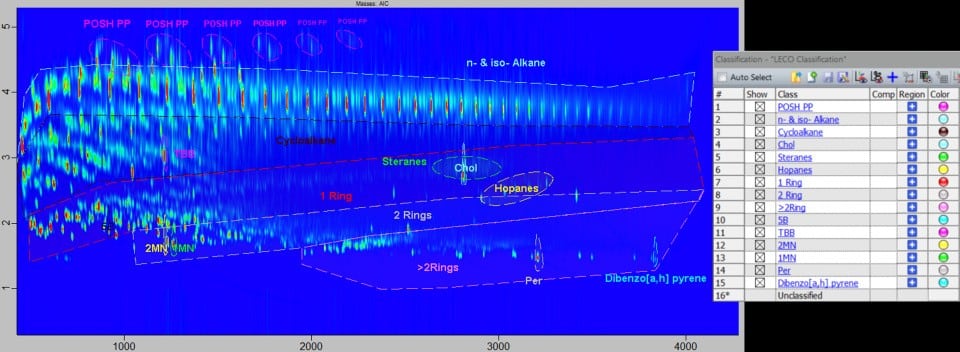

GCxGC (comprehensive two-dimensional gas chromatography) offers significantly enhanced separation power for complex MOSH/MOAH characterisation. Instead of relying on one separation dimension (where many hydrocarbons stack into unresolved signals), GC×GC enables structured two-dimensional separation. This increases peak capacity dramatically and creates structured separation patterns, where chemical classes fall into characteristic ‘zones‘ in GCxGC space.

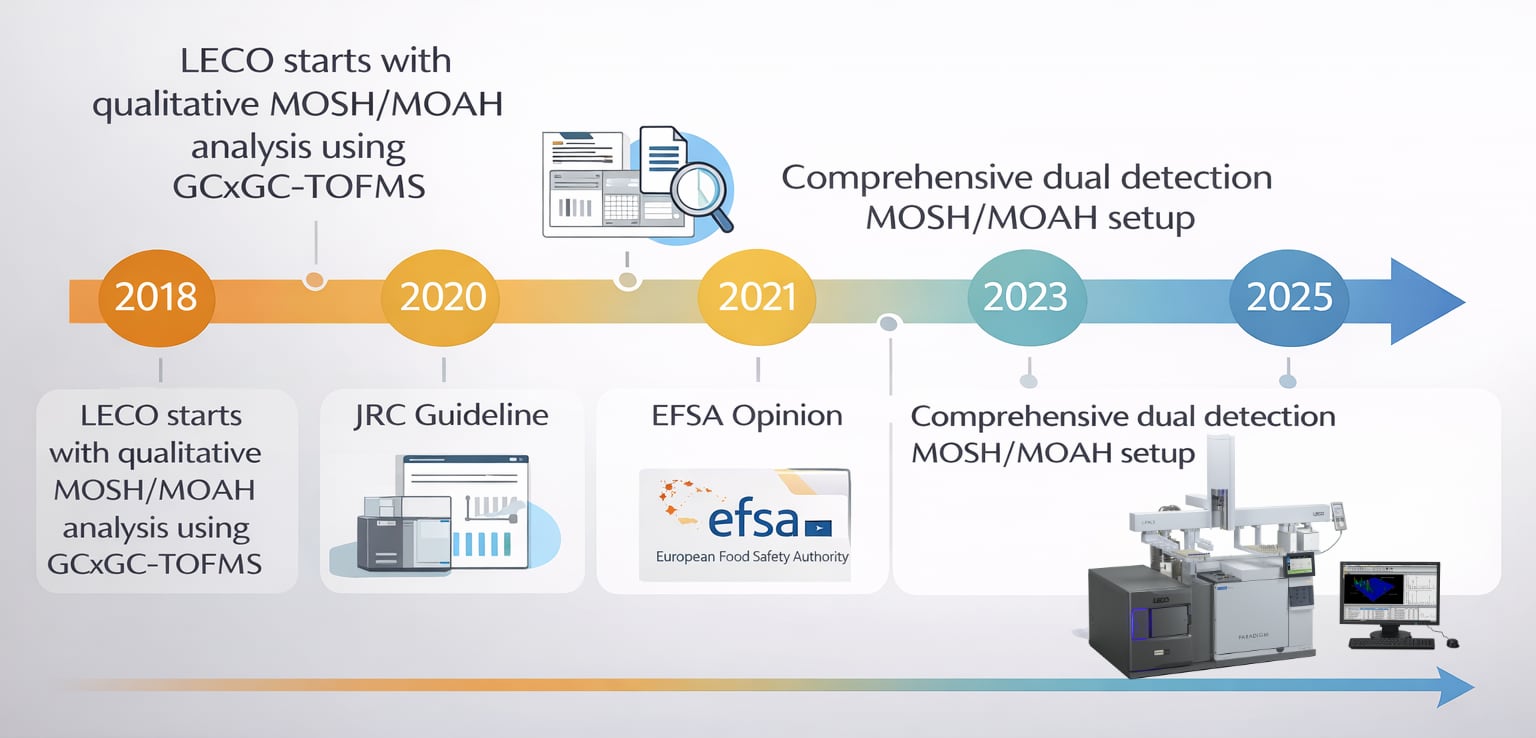

LECO began applying GCxGC-TOFMS to MOSH/MOAH as a qualitative confirmation approach well before dual detection became common in routine settings – building experience in how MOSH, MOAH, and biogenic interferences distribute across GCxGC space and how to translate that into practical decision support for labs.

Why dual detection matters: quantitation and qualification in one coordinated workflow

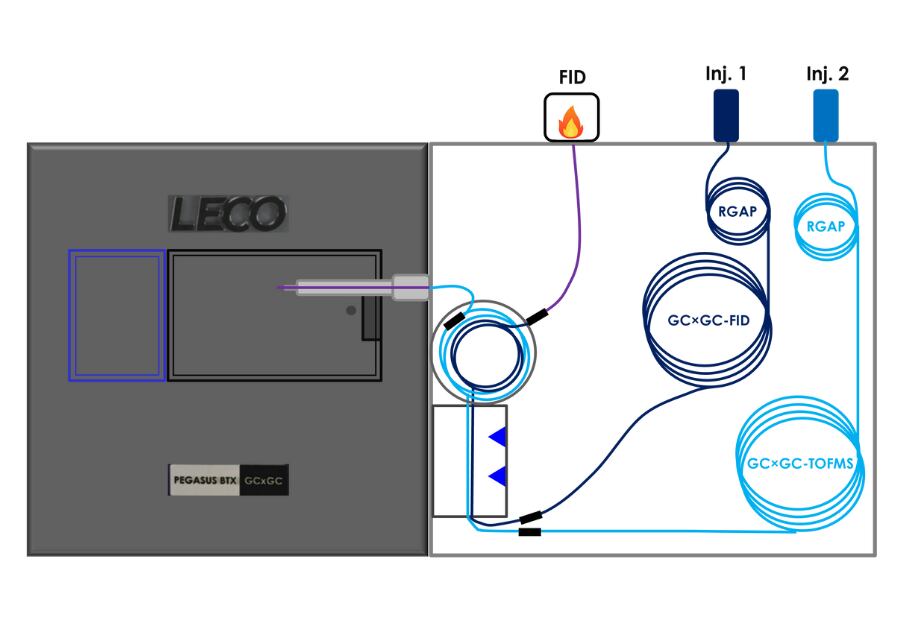

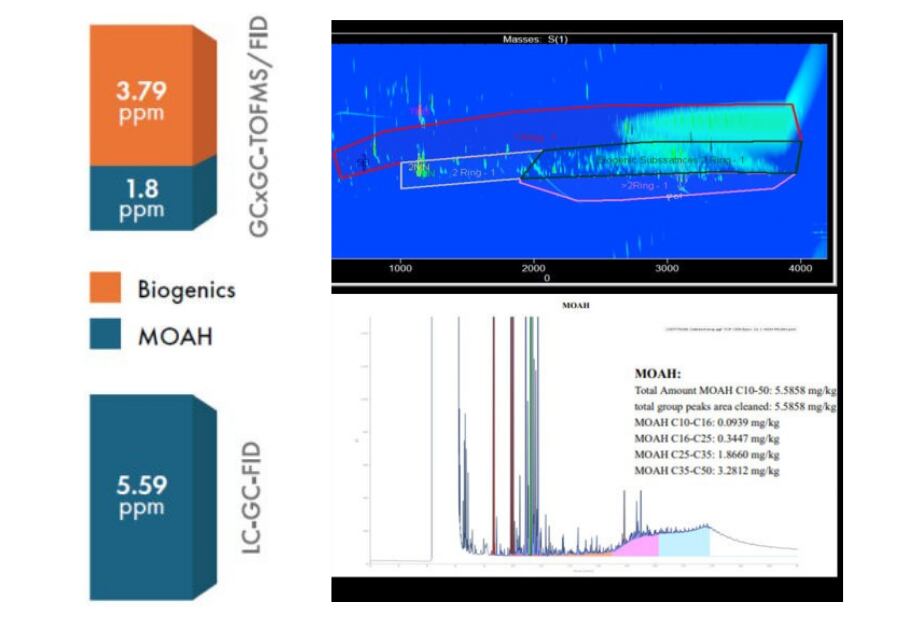

GCxGC gives separation power; TOFMS adds identification strength. But in MOSH/MOAH, quantitation is still often preferred by FID. The modern goal, therefore, is not to replace one with the other, but to combine them in a way that supports routine decisions:

- FID for quantitation of MOSH/MOAH fractions (strong, reliable mixture response)

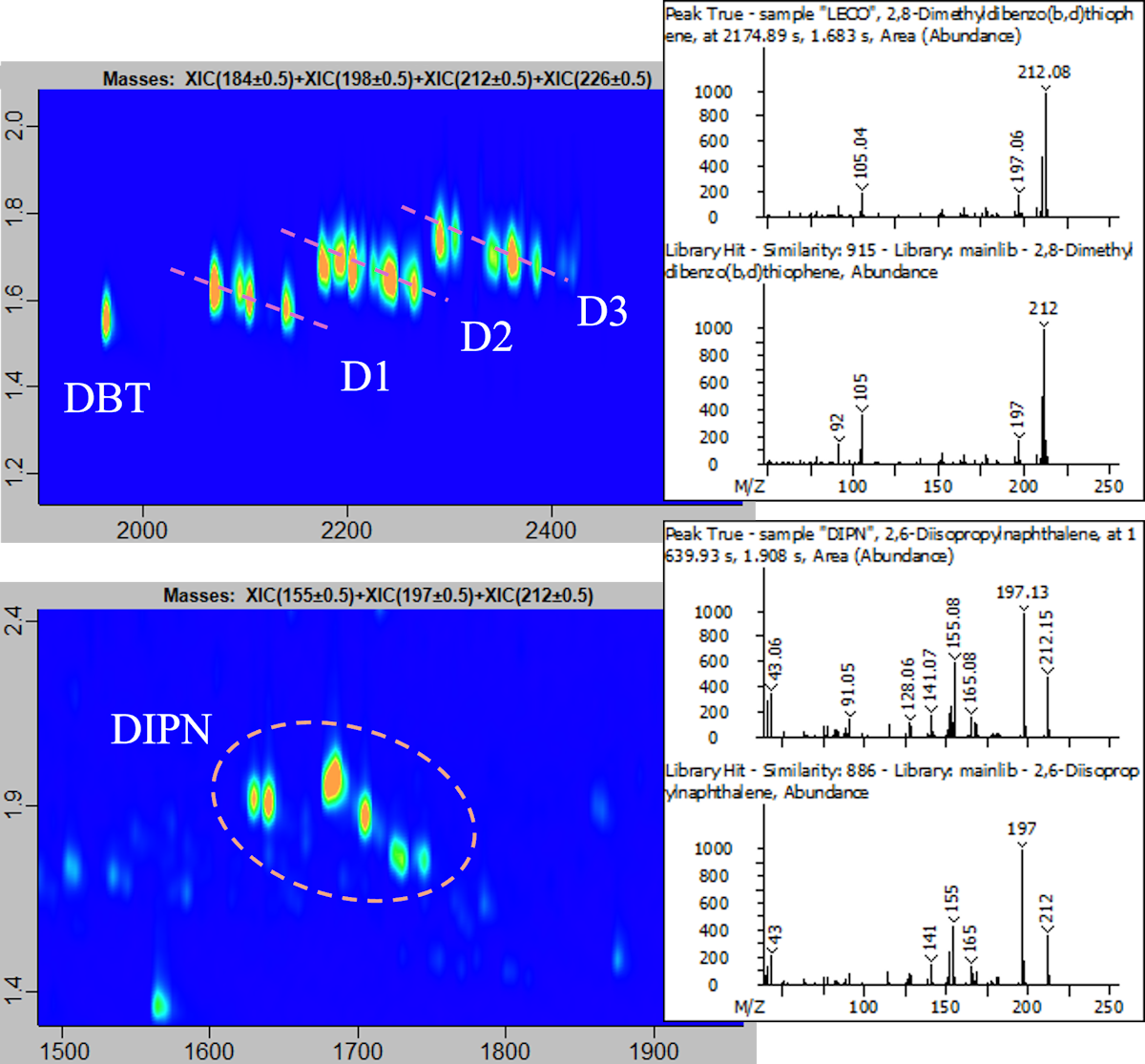

- TOFMS for qualification/confirmation, helping distinguish true mineral oil signals from naturally occurring interferences and providing additional information such as marker compounds and aromatic ring class patterns

In LECO’s MOSH/MOAH approach, this concept is implemented as a dual-channel GCxGC configuration where FID and TOFMS data are captured in parallel, enabling measurement and verification within the same analytical run.

Today’s workflow: keep the fractionation, upgrade the certainty

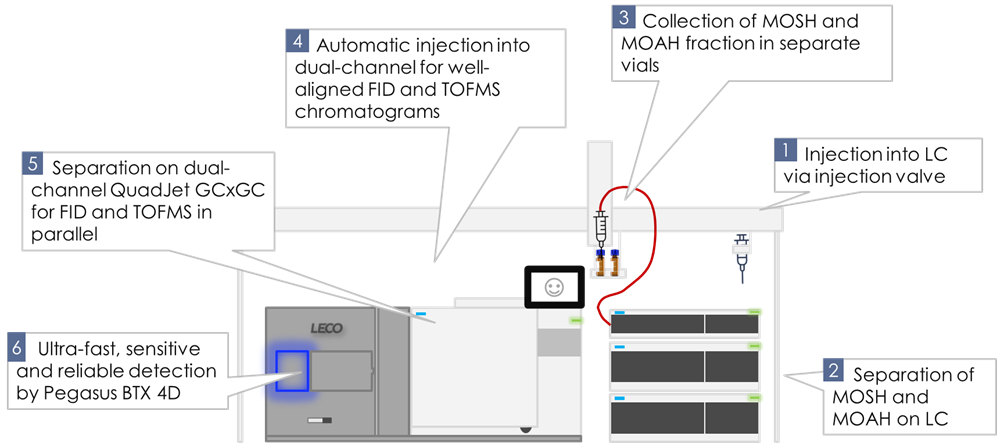

A key point in the evolution of MOSH/MOAH analysis is that fractionation remains central. Accurate MOSH/MOAH work still relies on sample preparation and LC fractionation to produce separate MOSH and MOAH cuts. What has changed is what happens next.

A modern ‘confidence workflow‘ looks like this:

- Sample preparation appropriate to the matrix

- LC fractionation to isolate MOSH and MOAH fractions

- Injection of each fraction into GCxGC

- FID quantitation supported by software tools designed to handle overlaps and background contributions

- TOFMS confirmation to identify interferences, confirm aromaticity patterns, and support source investigation

This approach can also be positioned as an extension to existing LC-GC-FID set-ups. For example, collecting MOSH and MOAH fractions into vials (‘fraction and collect‘) allows labs to preserve their front-end workflow while adding GCxGC-TOFMS/FID as a powerful second-stage confirmation and characterisation step.

What ‘better‘ looks like in practice: fewer false positives, more actionable results

The practical benefits of modern GC×GC-based confirmation map closely to the historical pain points:

- Distinguishing mineral oil from biogenic interferences such as squalene, plant waxes, terpenes, and phytosterols In many oils and natural products, biogenic hydrocarbons can dominate parts of the chromatographic space used for MOSH/MOAH quantitation. GCxGC separation plus MS qualification allows laboratories to separate and recognise these patterns so they do not inflate MOSH/MOAH values.

2) Supporting risk assessment with aromatic structure information MOAH is not ‘one thing’. The number of aromatic rings and the distribution of MOAH sub-classes matters for risk interpretation. GCxGC-TOFMS enables clearer grouping of MOAH by aromaticity patterns, which supports reporting that is more aligned with how MOAH is evaluated toxicologically.

3) Moving from ‘presence’ to ‘source insight’ Once a lab can confidently confirm the chemical nature of what it sees, it can also look for diagnostic markers. Certain compound families can point toward specific origins (e.g., printing inks, recycled board, lubricants), turning MOSH/MOAH analysis from a pass/fail test into a tool for root-cause investigation.

Closing summary

The history of MOSH/MOAH analysis is the history of turning a difficult analytical ‘hump problem’ into a confident, defensible decision. LC-GC-FID established the foundation for routine quantitation. The next era – already well underway – adds the separation power of GCxGC and the certainty of MS confirmation, so laboratories can quantify accurately, avoid false positives, and generate information that supports both compliance and root-cause understanding.

For laboratories seeking greater confidence in MOSH/MOAH analysis – particularly in complex or borderline samples – advanced GC×GC workflows combining quantitative FID detection with confirmatory TOFMS can provide valuable additional insight. LECO continues to work with analytical laboratories worldwide to support method development, validation, and real-world sample challenges. To discuss MOSH/MOAH applications, workflows, or specific analytical questions, contact the LECO team at moshmoah@leco.com