The skills gap in food manufacturing is still proving one of the biggest challenges for businesses to overcome, and they need to attract and retain motivated younger workers. But to do so, companies should be looking at optimising their workforce rather than their machinery, argues Redzone.

When it comes to food manufacture, a workforce crisis is going on, as highlighted by a report from Recruit Mint. This points to the ageing workforce, with many experienced professionals nearing retirement, but not being matched in numbers by younger replacements.

The problem is not unique to the UK. In the US, for example, Career Bee references a 2024 report from Deloitte and the Manufacturing Institute, which estimates that, by 2030, manufacturers could require nearly 4m new team members, but struggle to fill those positions due to an expanding talent gap, while the same report reckons that, as of 2025, 97% of manufacturers say hiring and retaining skilled labour presents a challenge to growth, with 75% citing it as their biggest barrier (Industry Survey, 2024).

In the UK, meanwhile, although food and drink make up the country’s largest manufacturing sector, contributing £37bn in gross value to the economy, according to the Food and Drink Federation, the number of vacancies per employees increased to 9.1 in Q3 2022 compared to 6.3 in Q2 2022.

What matters to Gen Z?

As with other sectors, the food manufacturing industry has struggled to overcome its perception as being a physically demanding and low-paid environment, not realising that advancing technology and the use of AI are on the cusp of transforming the industry, potentially making it an exciting place to work. Meanwhile, perceptions from employers and this largely traditional sector also need to shift to create an attractive environment for the younger generation. In short, the industry is faced with a problem: what interests Gen Z when it comes to applying for a job, accepting a job offer, and staying in the company. And what cause them to leave?

Compensation in the form of wages is only one aspect of the equation, argues Nevin Castellucci-Najar, sales director EMEA at manufacturing software specialist Redzone. He points to a report by McKinsey, which reveals other factors important to Gen Z employees include workplace flexibility, career advancement and meaningful work, alongside having caring colleagues and leaders. Meanwhile, food manufacturing companies need to think more outside the box and understand the cultural nature of the generation they are trying to attract. “Overlooking the culture on the shop floor or thinking their people aren’t capable enough are two of the biggest mistakes a manufacturer can make,” he says. Manufacturers should stop thinking in terms of what they think is best for their people and start thinking about how they can make it easy for their employees to flourish – and how they can remove the barriers for them to do so.”

The focus, he maintains, is still firmly on the machinery and equipment needed to do the job, rather than the personnel talent available and the career potential that they could achieve. Noting that manufacturing as a whole is almost 25 years away from where it should be in terms of automation, he highlights how Gen Z and younger generations coming up behind them operate in everyday life, with pretty much everything they do centred around digital technology on their phone – from booking an Uber, to doing their banking, listening to music or ordering a Deliveroo, for example. “The attitude that technology is something nice to have is no longer the way to think; it’s a requirement, it’s an expectation, particularly from the younger generation,” he says.

Now, AI has begun to play a transformative role in food manufacturing alongside other industries. According to Computer Weekly, AI can help create more inclusive hiring processes and can help HR leaders to identify early signs of people’s disengagement or dissatisfaction, enabling them to take early proactive steps to intervene. And a connected workforce is one of the most powerful tools an organisation can deploy in a manufacturing workplace, says Castellucci-Najar.

Identifying workplace challenges

Redzone has been working with manufacturers in the UK and Ireland for several years, helping them to identify workplace challenges. “The traditional way of thinking has always been ‘We need data, automation… maybe we need robots,” he says. “However, if a manufacturer focuses on its people, on applications that are designed to be easy and are reminiscent of what a younger generation of employees might already do on their phones, then you’re actually going to see more engagement from people. They are going to be way more excited to come to work and they are going to become better problem-solvers on the shop floor. Everything else then takes care of itself and is downstream from that culture.

“We often have to challenge manufacturers to see it that way – and push them to take a stance on what their problem actually is, so that they can come to a conclusion on the right solutions. We firmly believe that taking that connected workforce platform approach is the best.”

Bridging the knowledge gap

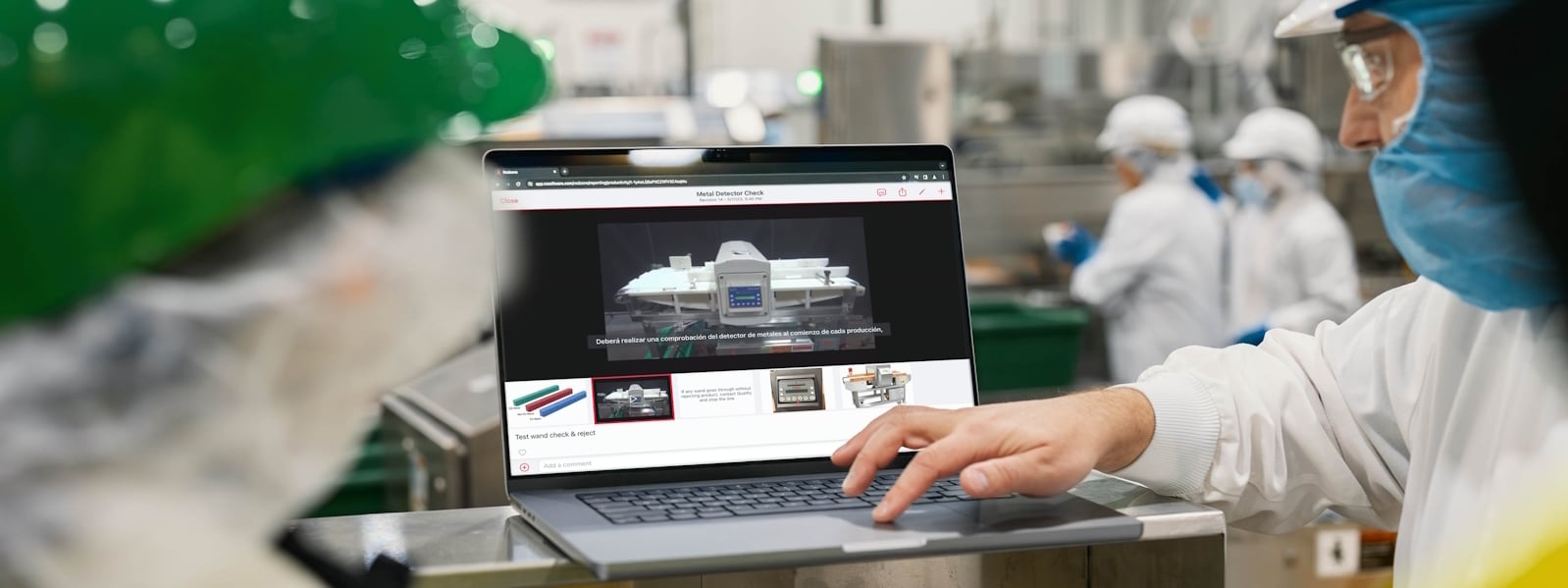

While AI operates best when off an existing interface, the power that it can bring to a manufacturing team in terms of recruitment, learning on the job and retention in the role is immense, he argues. As an example, he points to one of the biggest challenges in food manufacturing – the gap between the aging workforce coming up for retirement, with the wealth of manufacturing knowledge they possess, and the new recruits coming in who do not have the experience and expertise of this older generation.

“Baby boomers are retiring in large numbers every week,” says Castellucci-Najar. “In one case we worked on, there was an employee who had been working for the company in maintenance tech for several decades, responsible for keeping care of the machines. This employee was retiring – and it was a bittersweet moment, because the factory appreciated him and loved what he had done for them over his 30-plus years with the company. But then they launched Redzone towards the end of his career when he was about to retire and he was able to create a huge amount of video content that he was then able to pass down to the new workforce. He felt a lot of pride as a result, because he was passing on his legacy and, in turn, the company really appreciated that he was able to do so.”

Advantages of a connected workforce

Learning on the shop floor and throughout the business, including overcoming language barriers and delivering content in manageable bite-size format, is just one aspect of the advantages a connected workforce tool can bring. Other advantages include clarity of communication throughout a plant, problem-solving and pushing content to leadership, so that they clearly understand any workforce difficulties or frustrations – and can resolve them quickly. Content can be personalised to meet different requirements, as the employee in health & safety, for example, is going to have different needs to the employee on the shop floor.

Over and above this, companies are increasingly the target of cyber-attacks and, as Castellucci-Najar points out, the first target of attack for cyber criminals – through phishing, hacking etc – is often the newer employees in the company. So, rapid training in the relevant IT and safety information is another advantage an AI-enhanced platform can provide.

“Remove the barriers from your team, make it easy for them,” sums up Castellucci-Najar. “Any good leadership team will ask how they can remove barriers for their workforce, not say ‘this won’t work because they are not capable’. Manufacturers need to rethink the challenges in front of them and look at it from the workforce aspect. AI is not something people should be worried about – it’s something they should be embracing. Food and drink companies should be communicating the opportunities in their workspace, they should be creating an exciting environment for people to come to work – and an intuitive solution with a connected workforce is the perfect way to enable that to happen.”

Redzone’s connected workforce solutions are designed to unlock the power of frontline teams, delivering a 29% increase in productivity, a 74% increase in engagement and a 32% reduction in staff turnover. This is achieved through enabling frontline teams to use real-time data for improved productivity, problem-solving and communication with company leadership. Safety and compliance skills, alongside learning and on-demand mentoring are other assets of the company’s platform.

To discover more about Redzone’s connected workforce solutions click here.

To see how Redzone’s learning module works in practice, watch the video below: