There is a clear thirst to understand more about artificial intelligence and its application in the F&B manufacturing workplace – and both learning and business optimisation can begin with front line workers, says QAD Redzone

Mention artificial intelligence (AI) and the likelihood is that people have one of two reactions: either they are the doomsday sayers who believe that AI will be the first steps on the path to robots overtaking the planet and threatening humanity as we know it; or they are the enthusiastic supporters of the technology, who point out that it is simply another step down the road to modern science and that, if understood and controlled properly by humans, will provide huge benefits in terms of time and efficiency, particularly process optimisation in the workplace.

Indeed, an article in Food Navigator last year dismissed the doomsday theory, saying: “If used wisely, AI holds real promise to create positive disruption.”

For the food & beverage manufacturing industry, the potential for AI to be a positive disruptive force is gradually being realised. As an article in Food Manufacture pointed out in 2023, the ability of the technology to “factor in an inordinate number of data values, parameters and what-if scenarios can provide timely and accurate recommendations for almost every aspect of the food supply chain”.

“If you’ve never used AI before, it’s actually hard to conceptualise in your head how it might apply to your business”

Ron Davis, senior vice president of product engineering, QAD Redzone

At QAD Redzone, senior vice president of product engineering Ron Davis acknowledges the reticence of manufacturing executives as they try to figure out what values AI can provide to their business and really understand what it is. “If you’ve never used AI before, it’s actually hard to conceptualise in your head how it might apply to your business,” he says. “Also, we get a lot of questions around privacy and security – specifically how data is shared and used.”

When it comes to misperceptions, he says users feel that AI can, in some way, be held accountable for itself, but in fact the creators and users of that AI have to accept that accountability. As an example, he points to the case of two lawyers in the US, who were fined over the use of fake citations generated by ChatGPT, submitted in a court filing. “The lawyer is responsible for what the lawyer submits, not the AI; you cannot hold it accountable,” he notes.

Optimising the workplace

Instead of fearing AI and having the belief that it is “in some way replacing human beings”, Davis says people should view it as “reshaping the work they do, which is nothing new”. As he points out, in recent decades, technology has transformed the way people work every day, with skills advancing at an increasingly rapid pace, so it’s more a question of how humans utilise that technology to optimise operational efficiency that matters.

“One of the things that makes AI truly unique is its ability to deal with complexity,” he says. “Complexity has to do with the number of variables in an equation; the more variables there are, the more possible outcomes there are.”

As an example, he cites statistical process control (SPC), which he believes will continue to be replaced by data-driven manufacturing, AI-powered automation and AI-driven decision-making. For a typical food and beverage manufacturer, the number of items being managed in a direct inventory to create products can be hugely complex and complicated to track and calculate – and that’s before any macro influences such as global weather disruption, ingredient supply challenges and glitches in supply, for example, are taken into account.

On top of that, the level of compliance data for import and export in the UK is becoming increasingly complex, particularly with the type of red tape created by political shifts such as Brexit.

“When trying to solve complex problems, humans can only hold so many variables in their mental model at one time,” says Davis. “as compared to AI which can consider many times more variables and their possible outcomes. However, humans are still best at interpreting those recommendations.”

Championing the frontline worker

QAD is at the forefront of developing AI solutions for businesses, including food & beverage, around the world. For example, its QAD Import Management system includes a product classification tool, powered by AI, which helps to assign HS codes to products as part of the Harmonized System of the World Customs Organization. The system accelerates classification of a product by recommending a known HS code from the same or similar products. If the user confirms the code, the result is passed back to the system, which then ‘learns’ from the response and can adjust results for future comparisons.

However, its latest AI-enabled technology, Champion AI, is all about championing connected workers on the front line in plants to conduct their roles more efficiently and productively. Launched last year at Pack Expo 2024, the suite of AI-driven capabilities is designed to solve specific problems on the plant floor in a new way – providing predictive and prescriptive analytics to address daily challenges on the factory floor. These include detecting plant-wide outliers, delivering daily operation summaries, predicting run durations and identifying potential problems before they happen.

“It’s about aligning the people, processes and systems to continuously improve outcomes”

The company describes Champion AI as “a pragmatic solution” that equips workers with the tools to anticipate issues, optimise changeovers and analyse performance data, setting new standards for engagement and productivity. In short, it is designed to enhance operational efficiency and decision-making.

“People tend to think that engagement creates productivity,” says Davis. “However, that’s incorrect. When people are productive, they become more engaged as a result. At QAD Redzone, we’ve always been a champion for the worker. So, we’re building tools that help them raise the bar in their plants. It’s about aligning the people, processes and systems to continuously improve outcomes.”

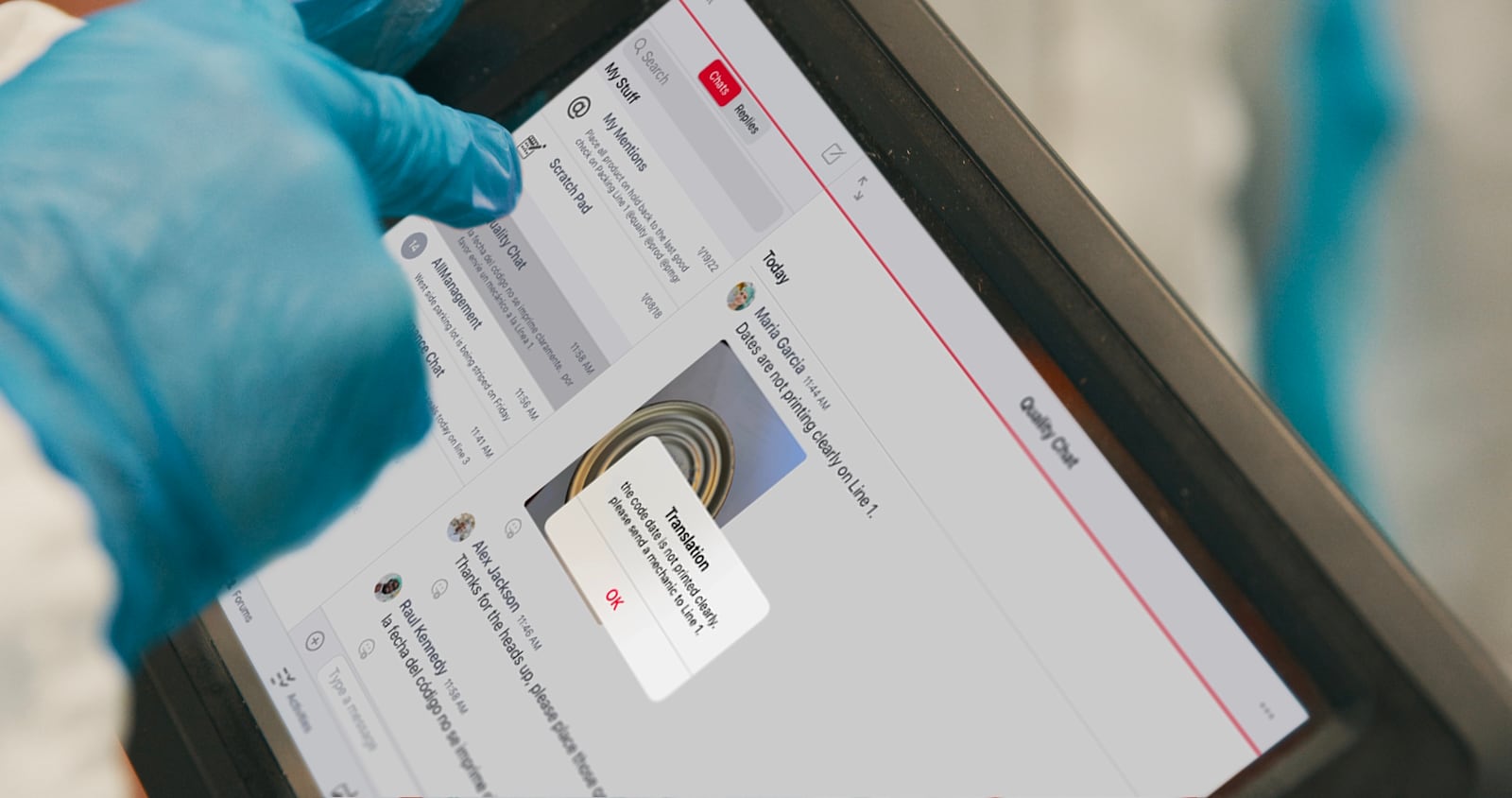

What makes QAD Redzone’s approach different is the focus is on frontline workers and their alignment to shared business outcomes. It is this that drives the inspiration behind its view of ‘humans plus AI’ not ‘humans versus AI’, he explains. “We focus on using AI to engaging workers in the real time by digging through piles of data and providing anomaly and outlier detection to help identify and troubleshoot issues. We focus on distilling all that complexity down into meaningful actions that workers can then take to execute better outcomes.”

Using AI to continually improve and drive those outcomes enables the company to give real time feedback on the front line. “Champion AI assists workers in achieving higher productivity, not by overwhelming or replacing them with technology, but by acting as an accessible intelligent assistant,” he adds.

“So, business executives intrinsically know that AI provides value, but it’s difficult for them to see the value they are getting,” he notes. “One thing that makes us unique is that we know the outcome and measure the value. So that when AI is used in Redzone, we can clearly demonstrate the value they are getting for their investment.”

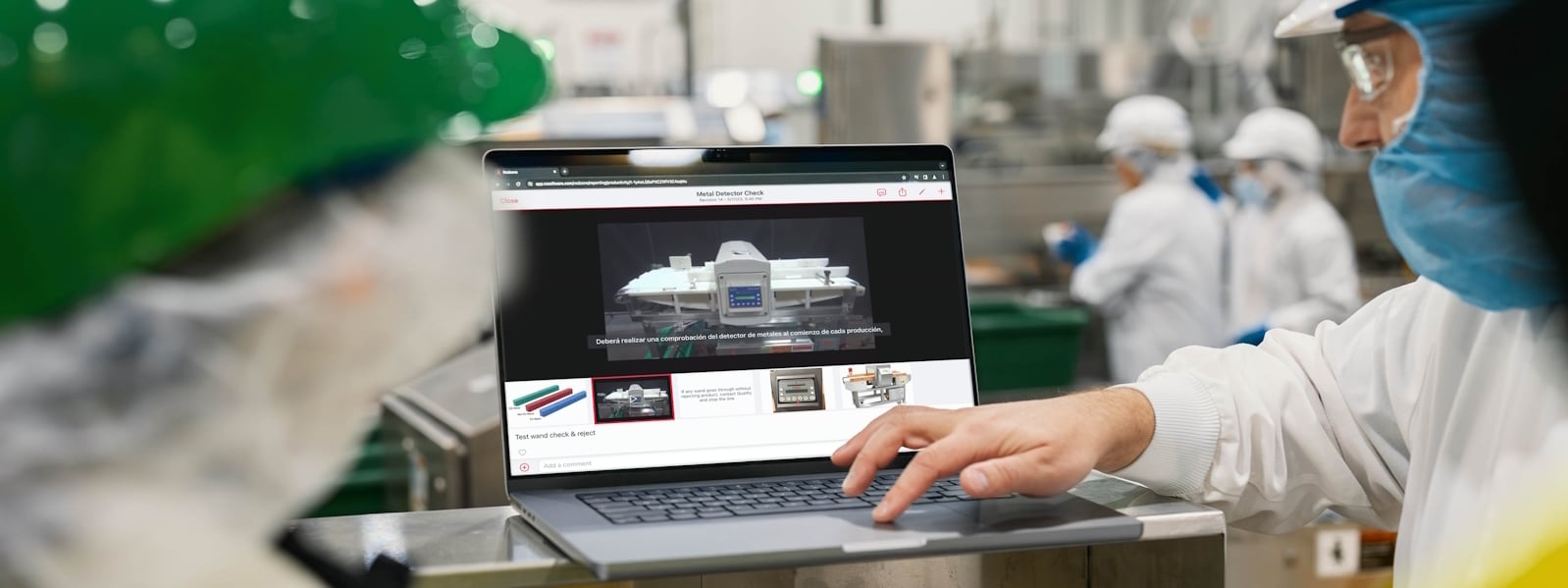

For example, QAD Redzone has long included AI to overcome language barriers in the workplace, transcribe and translate video content to improve plant efficiency and employee engagement. Now it also incorporates pragmatic AI to provide frontline operators recommendations and suggestions that will help them work more effectively.

Attracting a younger, enthused workforce

With a food and beverage manufacturing industry struggling to attract a younger workforce, one clear area where the use of generative AI may prove crucial is in recruiting a pool of new talent. A recent Global Survey by McKinsey & Co pointed out that employees are “far ahead of their organisations in using generative AI as companies have been slow to adopt in ways that could realise the technology’s trillion-dollar opportunity”. “To harness employees’ enthusiasm and stay ahead, companies need a holistic approach to transforming how the whole organisation works with gen AI; the technology alone won’t create value,” it says.

Davis agrees that, with the Baby Boomer generation retiring, a younger generation on the frontline, already familiar with AI from their educational and social upbringing, can use the technology to come rapidly up to speed with the knowledge held by their older counterparts and work their way up through the wealth of job opportunities at their disposal in manufacturing, from line operator to lead shift supervisor or quality management or even overall management within a company.

For an industry starved of younger talent, this might be the tipping point for greater adoption of AI and the benefits it brings. “To the youngsters of today ChatGPT is as transformative to their generation as Google was to previous generations,” he says. “They are going to expect to work in that way.

“So, people are really thirsty for AI, but they need to get the outcomes right. At QAD Redzone, we can show them how to achieve those outcomes with tools like Champion AI.”

To discover more about Champion AI and QAD Redzone’s suite of tools, go to https://rzsoftware.com/product/artificial-intelligence-ai or contact +44 (0) 121 740 0777.