Conching - intensive mechanical kneading that gives chocolate its smooth texture and taste - is as demanding as it is essential. It remains one of the most time-consuming, energy-hungry, and expensive stages of the chocolate production chain.

Today, operational inefficiency is not an option. Cocoa prices surged more than 250% in 2024 and show no signs of falling. Sales remain strong in the Americas, where treat-centric festivities are a long-standing tradition. But margins are under pressure. Switzerland’s iconic chocolatiers and their legacy of excellence continues to set the standard — but they too, face mounting raw material costs.

As Randall A. Sorrells, global food & beverage segment manager for NEMA Motors, explains: “Chocolate producers are caught between two non negotiables: delivering consistent quality, and protecting their bottom line. That means every wasted minute of conching is extra dollars and euros, at a time when costs are climbing across the board.”

Why tradition falls short at scale

Conching cycles have historically been safeguarded by overestimation. Operators add extra time as a safety buffer rather than risk under-developing flavour or texture. For small, boutique batches this hardly matters, but when scaled across dozens of runs a day, those unnecessary extra minutes add up to hidden inefficiencies.

Rigid, timer-based controls make the problem worse. Fixed-speed motors can’t adapt to changes in viscosity or torque, so subtle process shifts often go unnoticed; leading to efficiency that varies from batch to batch.

“Every chocolate maker wants to protect quality first, and rightly so,” Brith Isaksson, global food & beverage segment manager for ABB Drive Products added.

“But extra minutes at industrial scale quickly add up to megawatts. Beyond a certain point, more churning has no effect on taste — and the extra energy only eats into profits.”

Pairing precision with efficiency

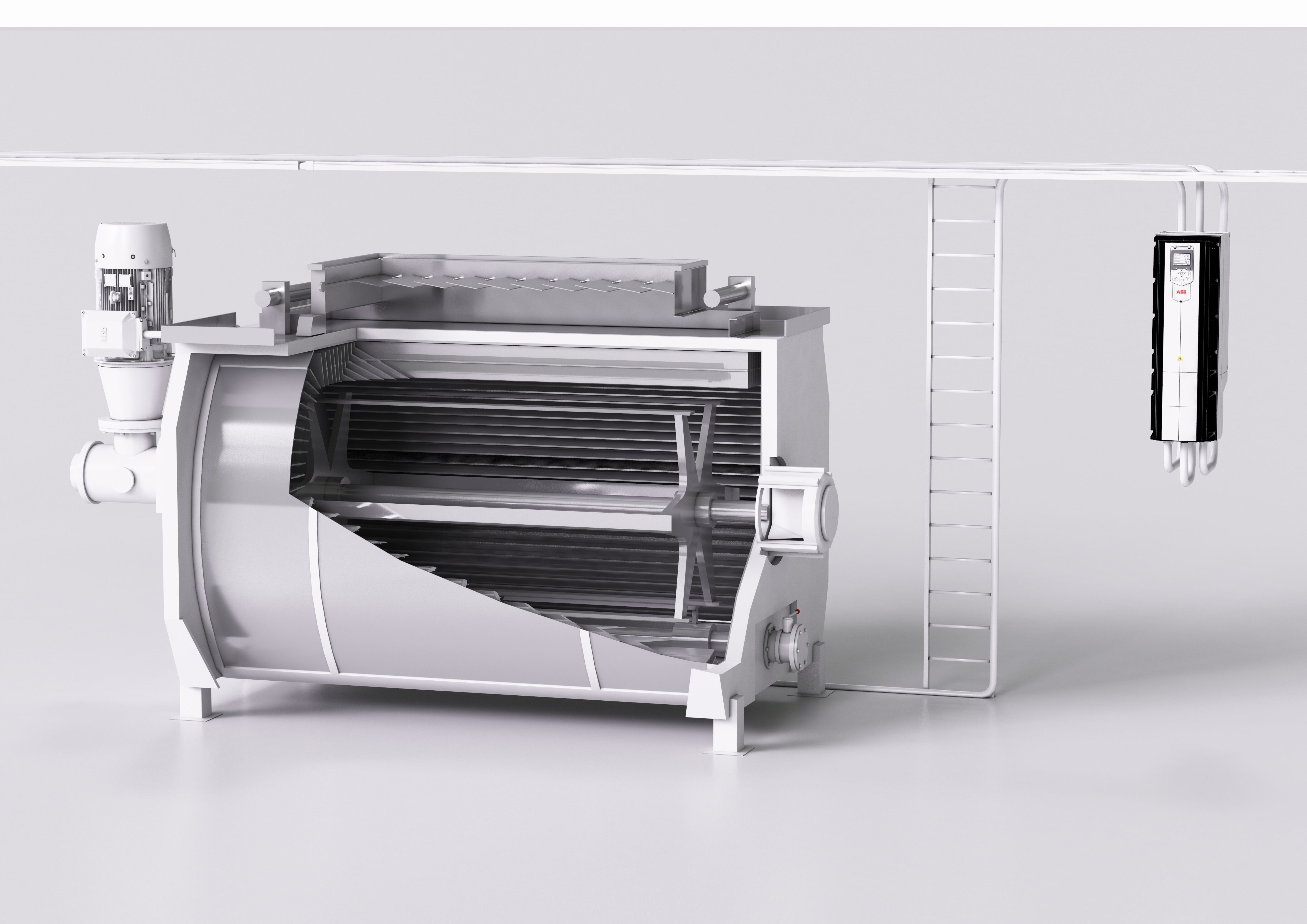

The answer lies not in pushing the process harder, but in making it smarter. High-efficiency electric motors, integrated with variable speed drives (VSDs), offer exactly that: controllable, responsive power that aligns to the precise demands of the recipe.

In North America, ABB’s stainless steel Baldor-Reliance Food Safe NEMA motors — designed to withstand stringent washdown requirements — can be matched with ACS580 drives. Together, they adjust torque in real time and stop the conche as soon as the chocolate is ready. The hygienic housing protects the integrity of the equipment, while the elimination of “over-processing minutes” frees up capacity for extra batches.

Globally, producers also have the option to select motors with IE5 “ultra-premium” -level efficiency. This includes ABB’s liquid-cooled IE5 Synchronous Reluctance motor (SynRM) — the first of its kind. Delivering very high efficiency with a compact footprint, these motors can reduce energy losses by up to 40% versus IE3 models, while their closed loop cooling adds stability when handling temperature sensitive foods like chocolate.

Sorells highlights why this matters: “There is a reason many chocolatiers over-conche. High quality chocolate is unforgiving, and under-processing is a big risk. ABB recognises this reality. That’s why our VSDs are designed to equip producers with tools that let them know precisely when a batch is done. Simply put, accurate conching maintains quality, reduces energy use, and maximises batches per shift.”

Isaksson added: “Modern drives give operators visibility they never had before. By capturing load and torque characteristics, they can see in real time when the chocolate is ready. That means eliminating unnecessary ‘safety minutes’ while keeping consistency; and ending each batch exactly on time.”

Efficiency proven in practice

Theory is one thing, evidence from the shop floor is another.

When Italian OEM SACMI Packaging & Chocolate upgraded its plant in Poland, it replaced traditional IE3 induction motors with ABB IE5 SynRMs guided by ACS880 drives.

The result was annual energy savings of 3–4% per mid-sized conche, running more than 7,000 hours. The carbon impact was equally striking: about 22 tons of CO₂ avoided annually for each conche, comparable to driving 56,000 miles in a passenger car. Quality was fully preserved, proving that modernisation can strengthen tradition rather than compromise it.

“This technology allows producers to expand without sacrificing quality,” explained Isaksson. “Efficiency gains and lower maintenance costs mean retrofit investments often pay for themselves within months, while also reducing Scope 2 emissions.”

Sorells underscores the added upside: “It’s not just about saving energy or cutting costs. Once the process is under control, chocolatiers get the freedom to experiment, whether that means trying new recipes or shaving time off a cycle, and still trust that the chocolate will come out just right.”

Keeping indulgence secure

Chocolate is more than a treat. It carries cultural and emotional weight across the globe. That’s why producers cannot allow spiralling costs to erode the quality and artistry that consumers expect.

By adopting precision-driven motors and VSDs, manufacturers gain the triple advantage of control, sustainability, and scalability. The result is simple yet profound: chocolate remains true to its craft, while production adapts seamlessly to modern challenges.

Because in the end, consumers should never notice the compromises that producers work so hard to avoid. What they should notice is exactly what chocolate has always delivered — indulgence.