It is broadly recognised that several major retailers are striving to increase the use of sustainable packaging materials for meat products. While mono-material packs offer enhanced recyclability, vacuum skin packs reduce the volume of plastic used without compromising shelf life.

As this transition remains ongoing however, modified atmosphere packaging (MAP) continues to be regarded as the best option for many products where extended shelf life and freshness is a key consideration.

It’s clear to see why this is the case. As a technology, MAP is generally more cost-effective in comparison to vacuum skin packaging when it comes to cheaper meats such as poultry, sausages, or minced meats like beef, pork, lamb and turkey. On the shelf, presentation is also more appealing to consumers, who have grown accustomed to seeing such products in trays with film lids.

It remains to be seen which way retailers will go in terms of wanting more of their meat products packaged in skin packs or remaining loyal to MAP. However, one thing is for sure, meat processors using MAP must be certain their packs are sealed effectively to avoid food spoiling earlier than expected. Failure to do so can lead to rejection of stock by retailers and the financial and reputational implications that come as a result.

Ensuring the seal of integrity in meat packaging

Taking this into account, decision makers at meat processing plants should explore options capable of giving them peace of mind where MAP is concerned, and where improvements can be found.

Seal integrity is the most important factor when it comes to MAP packs; however, that cannot come at the cost of poor productivity. As ever, throughput must be high to ensure quotas can be met, product wastage needs to be minimised, and production costs need to be low.

It is therefore highly advised that stakeholders in meat processing plants continue to invest in reliable, high-quality tray sealer solutions. By doing so, they also mitigate risks from wider challenges around cost increases, performance, operational efficiency and sustainability.

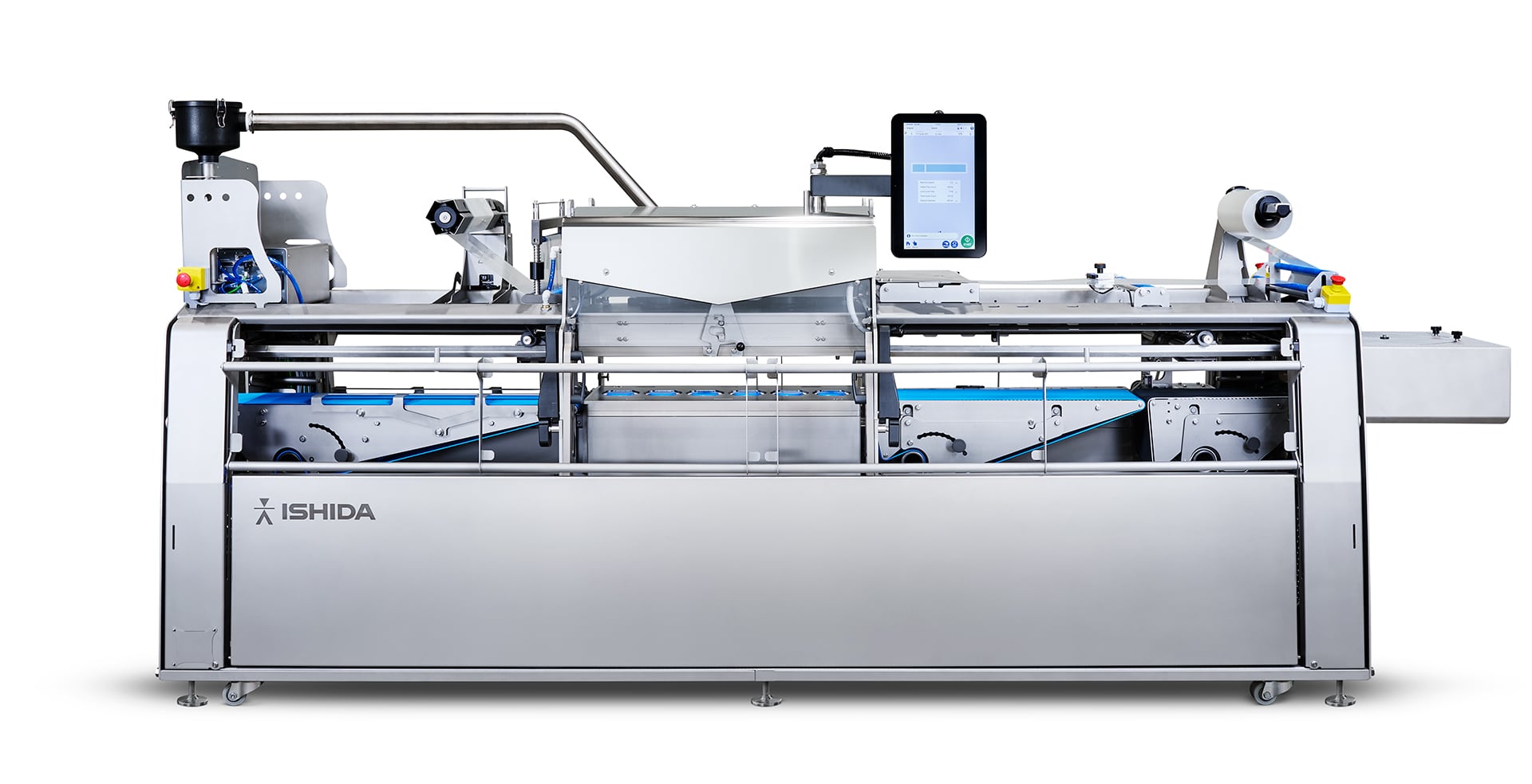

For example, Ishida’s latest tray sealer QX-800 is able to handle up to 17 cycles per minute for MAP packs, ensuring throughput is high. Additionally, it includes features such as a mechanical sealing system to improve the accuracy of sealing, while its patented tray transfer system minimises the possibility of spillage as trays are transferred.

It would also be wise for meat processors to consider future scenarios when it comes to pack formats. This is where the QX-800 excels, as it can handle multiple different formats through its innovative tooling. This means that, should retailers switch away from MAP packs to skin pack or other sustainable alternatives, the QX-800 can handle this changeover quickly, without meat processors having to further invest in new machinery and factory floor space.

Unseen, not undetected

But beyond these pressing challenges, a chief concern for MAP packs comes in the form of microscopic leaks. While the naked eye may be able to tell whether a tray is sealed, microleaks in films and packages can allow the gases used in the MAP process to escape, compromising product integrity. More concerningly, these leaks can be so small that they can pass the burst test, in which packages are exposed to high air pressures to identify weak points.

Though steps have been taken to better detect microleaks, methods of doing so typically remain primitive and open to error. These can range from a quality production manager simply squeezing the pack to feel air rushing through, or a packaging bath test in which packs are submerged in a water bath and observed for gas bubbles that would indicate a leak.

While any testing is better than no testing, findings from these procedures can only say what is happening with one pack at a point in time. But to avoid financial and reputational damage that can arise from incorrect sealing across packaging cycles, plant stakeholders must be able to look at the bigger picture.

Slow batch to fast-moving

Integrating leak detection for MAP applications so it takes place in-line can offer a promising way forward in this situation, reducing the risk of expensive stock returns or processors damaging their relationship with retailers.

Previously, leak detection was a slow batch process that could damage products selected for inspection, while the meat products that were packaged might then need to be thrown away, leading to food wastage and a loss of revenue.

Ishida’s AirScan leak detection system exemplifies this technology in action, testing products at scale without damaging even the rejected items. It can complete checks at up to 160 packs per minute, detecting CO2 leaks from apertures as small as 0.5mm, with reliable results from packs with carbon dioxide leaks as low as 10%. As a result, meat processors can increase throughput with little to no human intervention required.

Despite a retailer-driven push for more sustainable packaging, meat processors must continue to explore best practices through the seamless combination of tray sealing technology and in-line leak detection to reduce MAP failure rates and their financial and reputational repercussions.

Specialised expertise and advanced technologies including Ishida’s AirScan and QX-800 tray sealer can help ensure seal integrity and compliance with evolving regulations, ultimately helping businesses improve their operations alongside their financial income.