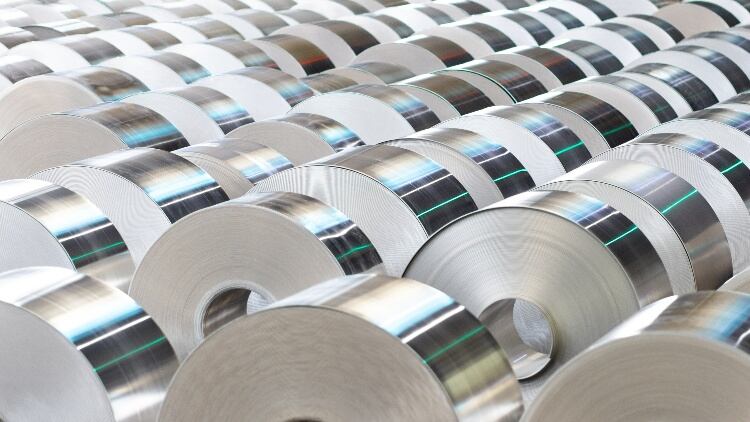

Amcor, which produces screwcaps for alcoholic drink bottles, developed the technology alongside aluminium supplier Aludium, with the product now independently verified by the Greenhouse Gas Protocol Standards as a low-carbon alternative for use in wine and spirit screwcaps.

According to Amcor, it is designed to produce less than four tonnes of CO2 equivalent per tonne of aluminium from raw extraction up until delivery.

This leads to a carbon footprint 50% below the European average, and 80% below that of aluminium produced in China. The reduced impact is the result of an increased use of recycled materials and the selection of low-carbon primary aluminium.

More products to come

Sustainability director at Amcor Bertrand Daru said the organisation wants to bring “more sustainable products to market” as part of a continued mission to meet its 2050 Net Zero goal.

“We are already leading the market with 96% of our products being recycle-ready,” Daru added. “But we want to go further and reduce the levels of CO2 emitted during manufacturing. Our aluminium screw caps now offer a more sustainable alternative for wine and spirits brands and distributors.”

Michael Brandner, specialities sales director at Aludium, said the firm was delighted with the partnership as part of its own push to install more sustainable practices.

“Thanks to heavy investments in Aludium assets, technology and processes, we are helping customers and end users achieve their carbon reduction targets,” Brandner concluded.

In related news, a spinout from the University of Edinburgh was awarded £3.6bn in funding to work on a machine that can reduce the amount of fossil fuels used in high temperature industrial process.