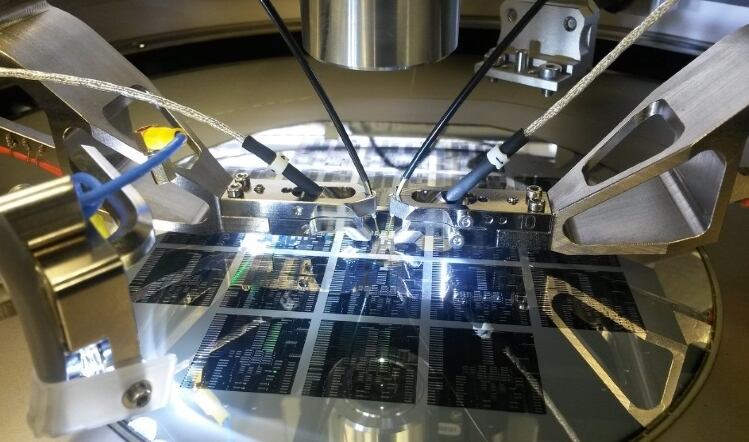

Developed by experts from parent company Industrial Tomography Systems (ITS), the Stream Line Rheometer and accompanying software provides a continuous measurement that does not interfere with the process and eliminates the need for sampling or lab-based testing.

According to Stream Sensing, the technology has been proven to provide and accuracy of 98% compared with offline rheology measurements.

‘Game changer’

Commenting on the launch, chief executive Ken Primrose described the technology as a game changer for fast moving consumer goods manufacturers and other process companies.

“Until now, they have used sampling solutions that measure flow properties during the manufacturing process, resulting in the loss of millions of pounds each year because of time and materials wasted while waiting for test results,” Primrose explained.

“Our technology provides accurate measurements of a key functional product quality in the production line in real time, and could result in huge savings, shorter lead times and better quality control. Ensuring the rheology is right is key to product quality and effectiveness.”

Investment for growth

Earlier this year, Stream Sensing secured a six-figure investment from the Northern Powerhouse Investment Fund – Maven Equity Finance, managed by Maven Capital Partners – to allow the business to fully commercialise the technology and support its planned growth.

“We’re already in the advanced stages of trialling the technology at processing plants of leading blue-chip manufacturers and are excited to be offering this unique digital technology to global processing markets as part of the Industry 4.0 revolution,” Primrose added.

Meanwhile, Mettler-Toledo Product Inspection has launched a series of smart-design, washdown-resistant product inspection systems, integrating sophisticated checkweighing and metal detection technologies for manufacturers of packaged food, including dairy and meat products.

The CM33 Washdown and CM35 Washdown combination systems are aimed at processors that require a quick-cleaning, advanced contaminant detection and precision weighing solution in one unit.