Feature

Leveraging genomics in microbial risk management

Q: Genomics and gene sequencing are ushering in a new dawn for microbial risk management, how will this technology revolutionise the food industry?

AL: The globalisation of food production and trade has made food supply chains longer and complicated foodborne disease outbreak investigations are now here to help keep people safe. The Food Standards Agency (FSA) estimates that of the 600 million cases of foodborne illness globally each year,1,2 2.4 million cases occur in the UK, costing a total burden of £9bn.

In addition to ensuring ongoing high standards of quality and food safety, a key part of the solution is developing scientific capabilities that can help to prevent microbial contamination in the first place. This helps protect health, strengthen food supply chains, and reduce food waste which in turn helps protect the planet’s resources.

Contributors

- AL: Alan Littlechild, Mars

- CT: Celina To, Oxford Nanopore Technologies

- EB: Eric Brown, US FDA

CT: Traditional methods for microbial testing can be time-consuming and may not recover all viable but non-culturable microbes, which impacts the perception on the size and severity of a contamination event. It can also make it difficult for food manufacturers to quickly identify and respond to potential food safety issues. This is where the strength of genomics, specifically Metagenomic Shotgun Sequencing (mWGS) and Whole Genome Sequencing (WGS), lies.

EB: DNA sequencing, is already beginning to permanently change the food safety landscape. It is now regularly used by industry and the public health community to pinpoint specific sources of contamination on farms and in facilities. It can quickly ascertain the nature of a food contamination event, revealing whether it comes from a persistent strain or from a sporadic source outside of a facility such as a raw ingredient.

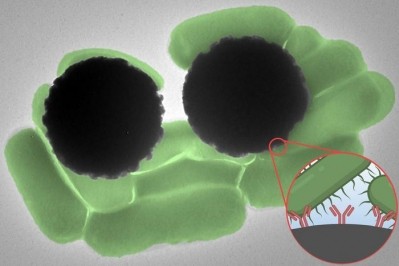

CT: Methods of mWGS and WGS using nanopore sequencing can help us understand the types of microbes involved in a contamination event by performing DNA sequencing, on-site and in real-time, without the need for culturing (in the case of mWGS) and/or amplification that make traditional approaches slower and more labour intensive. Nanopore sequencing can provide high-resolution data on microbial communities in food samples, allowing faster and more accurate identification of specific strains and potential foodborne pathogens.

EB: Moreover, WGS can provide unprecedented insight into root cause investigations allowing industry more time to react in the removal of pathogens from a particular product or its processing environment.

AL: Genomics is an exciting and rapidly evolving area of science and technology and a key focus for the food manufacturing industry. Since 2015, Mars has been working with partners in microbial risk management investing in capabilities, including genomics, through our Mars Advance Research Institute and Global Food Safety Center. Looking ahead, the food industry needs to leverage tools like WGS that can help connect events and, crucially, take us to a predictive and preventative space.

Q: How can we utilise integrated big data for the greater good to predict microbial risk, tailor interventions and prevent contamination?

AL: Food businesses around the world consume millions of tons of raw materials, through a global network of suppliers and customers, all of whom are generating vast amounts of data and using millions of man-hours of experience. The power in predictive analytics is in unlocking this data, often called ‘big data’; the future of food safety will no longer be about taking a sample and processing in isolation but taking all this data, uploading and interpreting to give us much richer insights.

CT: In the case of genomics, large amounts of WGS or mWGS data can be integrated with machine learning algorithms to identify – in real time – patterns or trends that could be indicative of potential arising food safety issues. This can help producers to respond quickly to potential risks before they become widespread. For example, a specific serotype of Salmonella may be responsible for a contamination incident in a multi-component food product. Using WGS data, you can quickly identify the serotype and determine its origin. The investigating team can then tailor their interventions to specifically target this strain of Salmonella, preventing further contamination.

EB: WGS data is also informative beyond source-tracking applications. Recent work is now demonstrating that WGS data can often reveal the nature of specific adaptations and fitness that persistent and recurring pathogens have acquired to thrive in the farm or food processing environment. Understanding the specific genetic or transcriptomic changes behind specific adaptive traits among Salmonella and other foodborne bacterial pathogens can offer potential insight into how better to control their presence in a specific facility or on a farm.

EB: This recent functional genomics concept in food microbiology has been coined ‘precision food safety’ genomics3 and holds great potential for more prescriptive pathogen mitigation strategies in the farm-to-fork continuum.

Q: What are the benefits and barriers to the sharing of genomic information of contamination incidents?

CT: As well as using sequence data to rapidly address the presence of a pathogen, supply chain actors may share detailed genomic information, in order to help identify the source of contamination quickly and develop targeted interventions. This could include hygienic zoning, new processing equipment or disinfection procedures, which can be more effective and efficient than broader measures to prevent the spread of the contamination and reduce the risk to public health.

EB: The benefits of sharing WGS data can include an immediate understanding of the context of a specific contamination event. WGS data can be made public through several databases and once uploaded, can join the hundreds of thousands of environmental and clinical foodborne pathogen genomes already present. As newly sequenced genomes are placed in the shared domain, the pathogens from which these genomes were derived can be analysed and evaluated with other genetically similar strains to better understand the role, if any, that a particular strain may have played in a broader contamination event, even providing insight into whether a strain was part of a potential outbreak.

CT: Despite these benefits, the uncertainty around legal and regulatory implications may be a barrier for the food industry to share genomic information. Case studies from regulators where genomic tools are used to help resolve a food safety incident may help boost confidence in data sharing.

AL: The challenge that arises is the fact that many organisations manage a fragmented and scattered data landscape of varying quality data. As a result, generated insights need to be carefully verified. While predicting microbial risk and preventing contamination can become more proactive, it’s critical that data sets are included from a range of verified and high-quality sources to generate valuable outcomes. The application of big data in food safety will require establishment of appropriate platforms for collection, storage, and analyses of a diverse set of data along with implementing safeguards for data rights and usage. Ultimately, we all need to be able to trust the data we are using in our food safety measures to ensure that we protect people and pets from foodborne disease and in doing so, protect the planet’s resources.

About the roundtable contributors

Celina To

Celina To is the commercial development manager, food testing at Oxford Nanopore Technologies. In this role, she has been working closely with the applied industrial markets team in supporting the food industry on the development of genomic solutions for food safety and quality. She graduated from Purdue University with a M.S. in Food Microbiology and California Polytechnic State University with a B.S. in Food Science. Celina has held a variety of positions throughout her career, including research assistant at NASA Johnson Space Center and Hilmar Cheese Company, quality assurance supervisor at Safeway-Albertsons, and technical support and sales manager at Hygiena LLC. She continues to be an active member at multiple food industry associations, some of which are planning and microbiology committees, to support the exchange of new knowledge and best practices in addressing emerging issues in food safety.

Alan Littlechild

Alan Littlechild is the Q&FS and R&D systems head at Mars Wrigley. In this role he drives global improvements to ensure the correct balance of value creation and business/consumer protection in Mars programmes to ensure brand longevity and consumer trust. Alan has over 25 years of experience across R&D, supply and commercial functions, working closely with industry peers. As a people leader, he is focused on developing talent through the provision of continuous learning and growth opportunities. In his spare time, he volunteers with the non-profit Candorful, helping service personnel and their families transitioning from military service into civilian roles.

Dr Eric Brown

Dr Eric W. Brown has been with the Food and Drug Administration’s (FDA) Center for Food Safety and Applied Nutrition (CFSAN) since 1999 and has served as director of the division of microbiology in the Office of Regulatory Science since 2011 (2009 Acting). Here, he oversees a group of 60 food safety microbiology researchers, students, and supports scientists engaged in a multi-parameter regulatory and applied research programme to develop and apply microbiological and molecular genetic strategies for detecting, identifying and differentiating bacterial foodborne pathogens from foods and the surrounding environment including Salmonella, Listeria, and shiga-toxin producing E. coli.

His laboratory has been instrumental in adapting next-generation sequencing technologies to augment foodborne outbreak investigations and to ensure preventive control and compliance standards at the FDA, including the establishment of the GenomeTrakr whole-genome sequencing network for food safety. Dr Brown received his M.Sc. in Microbiology from the National Cancer Institute/Hood College joint programme in the biomedical sciences in 1994 and his Ph.D. in Microbial Genetics from The Department of Biological Sciences at The George Washington University in 1998.

He has conducted research in microbial evolution and genetics as a research fellow at the National Institutes of Health, the U.S. Department of Agriculture, and as an assistant professor of microbiology at Loyola University of Chicago. He has been a member of the American Society for Microbiology since 1994 and was inducted as a fellow of the American Academy of Microbiology in 2015.

He has co-authored more than 275 refereed publications and book chapters and has presented nationally and internationally more than 140 times on the molecular differentiation, evolutionary genetics, and ecological persistence of bacterial pathogens, including 37 internationally invited venues.

References

- Food safety World Health Organization. Available at: https://www.who.int/news-room/fact-sheets/detail/food-safety (Accessed: 05 June 2023).

- The burden of foodborne disease in the UK 2018 Food Standards Agency. Available at: https://www.food.gov.uk/research/foodborne-disease/the-burden-of-foodborne-disease-in-the-uk-2018-0 (Accessed: 05 June 2023).

- J. Kovac, mSystems. 2019 Jun 11;4(3):e00164-19. doi: 10.1128/mSystems.00164-19