Meat smoking tech from GEA offers smokehouse-style taste

Traditional wood smoking takes a long time to complete per batch of product and involves high levels of manual labour, so it can be difficult to recreate cost-effectively on a large scale.

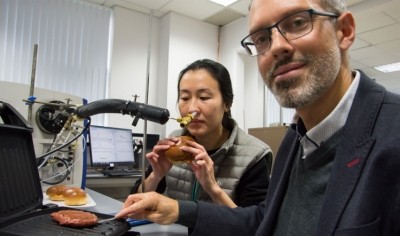

The new in-line smoking technology can be based on either smoke condensate or incorporate traditional smoke from wood chips. It is produced using the bespoke CookStar, GEA’s leading spiral oven.

In a world first, GEA has been able to incorporate in-line smoking into a spiral oven, enabling it to supply primary smoke condensate into the cooking process. Purified smoke was generated during the in-line cooking process, resulting in clean label smoked cooked products, GEA said.

Increased productivity and consistent quality

Integrated into the latest version of its CookStar oven, its smoking solution allowed food processors to increase productivity and deliver consistent quality by circumventing rack ovens and long, labour-intensive batch smoking processes, it claimed.

In partnership with smoking specialist Red Arrow, GEA has developed the SuperHeatSmoke, based on an atomized smoke generator with nozzles integrated into the CookStar. These are used to create a smoke cloud and smoking environment using purified smoke condensate.

The process takes 25-120 minutes depending on the application. The quicker process meant less moisture was lost from the product, boosting final yields, GEA said. The products are smoked as they are being cooked, further saving time along the line.

Opportunities for innovation

There were extensive opportunities for innovation, as processors could use condensates with different flavour intensities and colours, according to the company. Flavour preferences can be saved in the machine’s control system as recipe settings, speeding up production set-up and ensuring consistency, with uniform flavour and colour.

The CookStar's two cooking chambers offered flexibility to create different smoking conditions, independently managed. The two chambers can run on separate temperatures, humidity levels and smoke flavours to influence final product characteristics.

The GEA SuperHeatSmoke operates at temperatures above 100°C. The process is designed for chicken, beef, pork, seafood and vegetarian components.

HotSmoke for low temperature smoking

However, for products traditionally smoked at lower temperatures, GEA has launched the HotSmoke, which is designed for pork bellies and bacon. The system comes with the option of using either smoke condensate, or alternatively, smoke generated from wood chips.

The systems are aimed at processors seeking clean label solutions, those involved in the smoking industry seeking to move towards more efficient methods and companies already using the CookStar looking to start offering smoked products.

“Both options produce foods consumers love, whilst allowing processors to keep their running costs low,“ said GEA food technologist Ben Kop.