More food industry warehouse automation needed

“UK businesses are under tremendous pressure to perform – and the challenges are becoming tougher,” claimed Matt Hatson, business solutions sales director for Dematic northern Europe.

“Customers are ever more demanding, wanting later and later cut-off times for next-day deliveries; margins are becoming tighter as competitive positions harden; and labour costs are on the rise.”

The NLW, which increased the labour rates for those aged 25 and over to a minimum of £7.20 an hour, has added to the cost burden of labour-intensive DC operations, said Hatson.

“And now Brexit has cast a shadow over the future availability of abundant labour resources from Europe.”

Shorter processing times

While pushing back cut-off times for next-day deliveries might secure competitive advantage, this solution comes at the price of shorter processing times for fulfilment operations, argued Hatson. Instead, businesses need to tackle the pressing issue of low productivity, he said.

There was a huge gap between productivity levels in the UK and those of other G7 advanced economies, Hatson noted.

“According to the Office for National Statistics, international estimates of productivity in 2014 revealed that output per hour in the UK was now 36 percentage points behind Germany, 30 points below the US and is trailing France by 31 points.”

Because labour has been so cheap until relatively recently, many businesses have reasoned that it was unnecessary to invest in productivity enhancing technology, said Hatson. But that situation had changed, he added.

“High availability of flexible, low-cost labour has allowed low-productivity business models to survive in the UK – but for how much longer?” asked Hatson.

“If retailers and manufacturers are to grow their businesses, and still offer customers what they demand in terms of service, then productivity must be significantly improved.

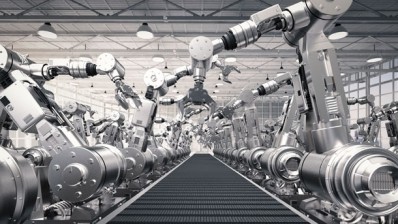

‘Higher levels of automation’

“And that comes down to introducing higher levels of automation to boost the productivity levels of those individuals working in the distribution centre.”

Flexible and scalable automation systems were now available from companies, such as his own, that offered fast payback, he added.

To demonstrate how flexible automation could significantly boost productivity, Hatson cited the example of Coop Denmark, where Dematic’s Multishuttle technology had been linked to the its RapidPick intelligence to create a fast, reliable and scalable goods-to-man picking operation that had dramatically increased productivity from 140 to 450 items picked an hour.

Using technology wisely and proportionately can deliver the results needed to solve the productivity issue, he added.

“Importantly, automation not only boosts productivity, but it also reduces error rates too, so costs and actions associated with rectifying mis-picks and dealing with disappointed customers are reduced,” said Hatson.