What you do when PLCs go wrong

While PLCs are commonly viewed as ‘black boxes’ by those unfamiliar with them, they are in fact easier to troubleshoot than old hard-wired control systems, according to Jonathan Wilkins, head of marketing with industrial automation component supplier European Automation. However, that doesn’t mean they don't go wrong, claimed Wilkins, who listed the main potential problem areas.

Problems

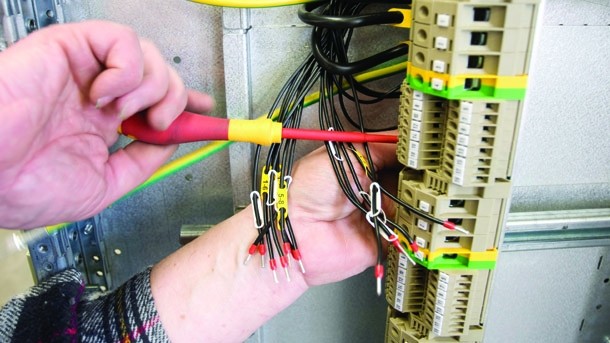

The first relates to input/output (I/O) modules. While people assume that when something goes wrong with a PLC, it is due to internal processor problems, they are usually wrong, claimed Wilkins. “A big percentage of problems are the result of I/O modules or field equipment,” he said. “It is not difficult to diagnose whether the problem is emanating from the I/O system or in the processor.”

If the problem is traced back to a specific I/O module, this means that it is usually an external one, like a wiring error, he said. If it is an internal problem, this could actually result in erratic behaviour, large groups of failures, or even total failure of the PLC system.

One of the first checks to carry out is the electronic ‘integrity’ of the ‘ground’ of PLC. The power and ground wiring also needs to be examined, to ascertain whether it is loose, corroded or has damaged connections. The power supply should also be checked.

Another problem for the PLC can be the effects of electromagnetic interference (EMI) or radio frequency interference (RFI), said Wilkins. These can be related to lightning strikes, welding in the area or handheld radio transmitters. “Improvements in shielding, grounding and power conditioning can combat any EMI or RFI problems,” he said.

Disrupt and corrupt

Frequency interference, power and grounding are all problems that can disrupt and corrupt the PLC’s memory, so it is crucial to verify the program is still correct compared with a backup copy on tape, disk or in the cloud, he added.

Lastly, Wilkins pointed out that when PLC troubleshooting, a top aim is to find out why the internal status of the PLC (what the PLC thinks is happening) is in conflict and not in agreement with the external situation (what is actually happening).

This involves determining the status of the relationship between physical I/O modules and I/O instructions in the PLC program. A handheld unit or PC can be used to check the internal status of the I/O in question, said Wilkins.