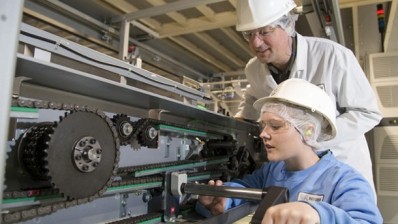

Food sector needs more engineers urgently

With skilled overseas staff likely to be squeezed by tighter immigration rules, the UK would be even more dependent on home-grown talent, some have argued.

More engineers will be needed who have a strong grasp of advanced technologies, as these will determine companies’ future competitive edge. But the signs are not promising, warned the EEF, formerly the Engineering Employers’ Federation.

New research on investment plans released by the EEF and software firm Oracle has revealed skills gaps as manufacturers prepared for the ‘fourth industrial revolution’ (4IR) over the next decade.

Though technologically and digitally driven, the research suggested that manufacturers were prioritising investment in skills over software and machinery.

Extra £27bn a year

According to another report from EngineeringUK, the body set up to promote engineering, if engineering employers in the UK were to take advantage of the extra £27bn a year of revenue by 2022 promised from tapping into these new technologies, 257,000 new vacancies would need to be filled.

According to the EEF report, 83% of manufacturers needed to invest in staff skills and 65% in management skills in order to adopt new advances in technology.

At the same time, getting fit for 4IR would require new machinery (51%) and software (38%) – but 34% of manufacturers also said new staff would be required.

The research also found that, as they geared up, firms were already investing in multi-purpose production lines (38%), capital equipment with embedded sensors and controls (33%) and cloud solutions (29%).

And, with an eye to the future, within the next five years 18% of manufacturers would have invested in 3D simulation of manufacturing processes, augmented reality (17%) and fully autonomous robots (16%).

‘Crucial for UK manufacturing’

“4IR will be crucial for UK manufacturing,” said EEF chief economist Lee Hopley. “Manufacturers are aware that it will be a game changer – not just for investment in technologies, but for the cutting-edge, high-level skills required alongside.”

EngineeringUK said that getting more children to study science, technology, engineering and mathematics (STEM) subjects would be key to meeting this demand.

In response to this, industrial components and engineering services firm Neutronic Technologies has just published a report that investigated what the obstacles were.

It found that more than one in seven people believed that not enough was currently being done by the nation to encourage children to study STEM subjects.

“The shortage of graduates seeking out careers in engineering is a huge concern for everyone in the industry. The world’s demand for talented engineers is growing,” said Neutronic’s md Neil Gallant.